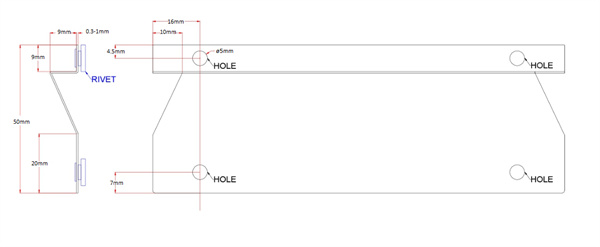

I. ‘Z’ Shape Profile: (according to confirmation by both parties)

Physical display drawing:

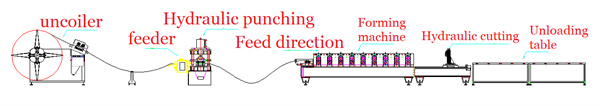

II. Process flow:

Passive uncoiling (Uncoiling and leveling two in one) → Servo hydraulic punching → Forming machine → Length cutting → Receiving

III. Machine Components Data:

1. Uncoiler:

(1) Uncoiler : Passive feeding, hydraulic expansion

(2) Loading Weight : 5T

(3) Uncoiler Coil I. D : 508mm

(4) Rolling range : 450-530mm

(5) Hydraulic uncoiler system power : 1.5KW

(6) Hydraulic pump uncoiler system : gear pump or a vane pump

(7) Leveling mechanism structure : 2-roller pinch, 7-roller leveling

(8) Leveling roller shaft diameter : about φ52.5mm

(9) Leveling roller material : high quality 40Cr

2. Servo punching mechanism (hydraulic):

(1) Servo feeder power : 1.9kw

(2) Four - pillar hydraulic punching mechanism : single position

(3) Punching die : 1 set

(4) Upper and lower template material : high quality 45#carbon steel

(5) Upper and lower die material : Cr12Mov or SDK11

(6) Hardness of upper and lower die heat treatment : HRC58-6

(7) Hydraulic system power : 11KW (single circuit)

(8) Hydraulic system cooling : air cooling

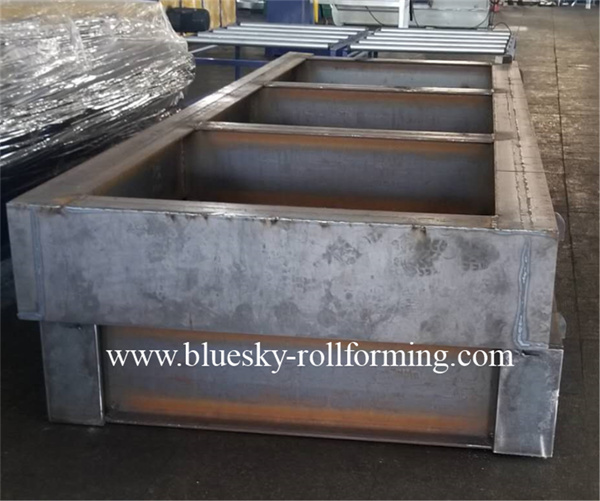

3. Roll Former:

(1) Main frame: High quality steel after welding and tempering

(2) Forming machine type : wall plate chain drive

(3) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

(4) Shaft diameter :Φ70 (HRB Bearing)

(6) Forming machine motor power : 7.5KW (hard surface reducer)

(7) Forming machine line speed : 0-15m\min

(8) Roller way nos : 9 nos(plus three roller regulate)

(9) Rolling thickness : 0.3-1.0mm (stainless steel, cold rolled steel)

(10) Expanded width of rolled material: based on the actual test plate width

(11) Length limit : ±1.5mm

(12) Roll material : Ccr15 quenching treatment (HRC58-62)

(13) Roll hard chrome plating : ≥ 0.05mm

4. Hydraulic cutting(Servo tracking):

(1) Cutting type : after molding stop hydraulic cut off

(2) Cutting blade : 1 Pay.

(3) Forming cutting mold material : Cr12M0V

(4) Heat treatment of cutting blade : quenching treatment (HRC58-62)

(5) Motor power of hydraulic station : 4kw

(6) Hydraulic system solenoid valve : Beijing huade

(7) Hydraulic station oil pump : vane pump

5. Unloading table:

(1) Structure of unloading roller: Angle welding, drum type (no power)

(2) Material unloading roller size : 1500mm * 2pcs

IV. Equipment structure

The main machine is composed of passive Uncoiler, Servo hydraulic punching mechanism, Roller forming machine, hydraulic cutting mechanism, material receiving mechanism, hydraulic system, electronic control system, etc.

| Raw Material | Type | Stainless Steel, Cold Rolled Steel |

| Thickness | 0.3-1mm | |

| Performance | Speed | Max. 15 m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |