I. Profile drawings: (according to confirmation by both parties)

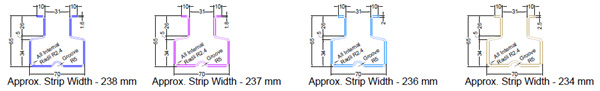

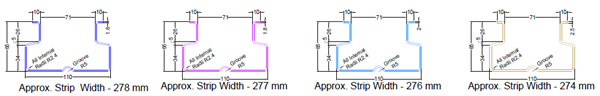

RNS Upright Sr 70*65mm

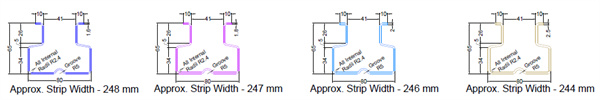

RNS Upright Sr 80*65mm

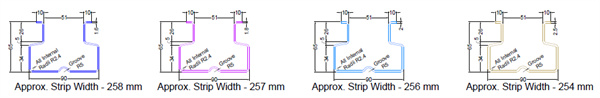

RNS Upright Sr 90*65mm

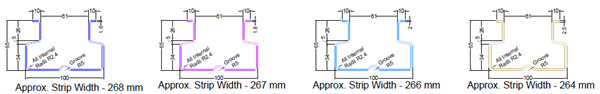

RNS Upright Sr 100*65mm

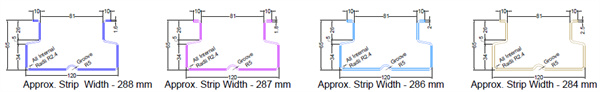

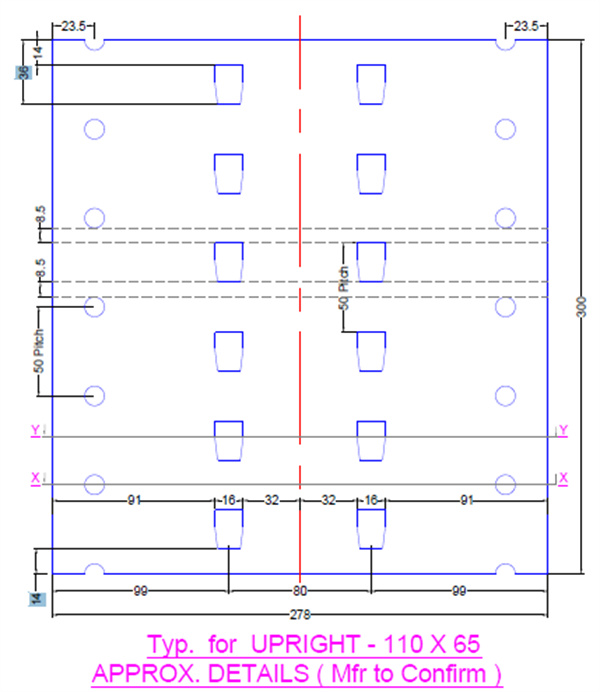

RNS Upright Sr 110*65mm

RNS Upright Sr 120*65mm

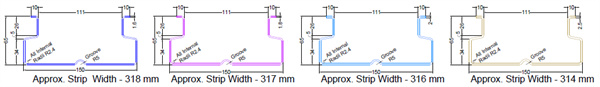

RNS Upright Sr 150*65mm

II. Process flow:

Automatic unwinding ----> Pinching and Leveling ----> Hydraulic punching (servo) ----> Roll forming -----> Fixed-length cutting (servo tracking) -----> Unloading table.

III. Main Component Data:

1. Uncoiler:

1). Uncoiler : automatic unwinding, hydraulic tensioning

2). Uncoiler load : 4 T

3). Inner diameter of uncoiler : 508 mm

4). Supporting roll range : φ450-540 mm

5). Uncoiler hydraulic system power : 2.2 KW

6). Uncoiler hydraulic system oil pump : gear pump or vane pump

2. Leveling machine:

1). Two-roller pinch, seven-roller leveling

2). Leveling roller shaft diameter : about 90mm

3). Leveling roller material : high quality 40Cr

4). Leveling shaft heat treatment : surface high frequency quenching treatment

5). Leveling machine motor power : 3 KW

6). Reducer : worm gear

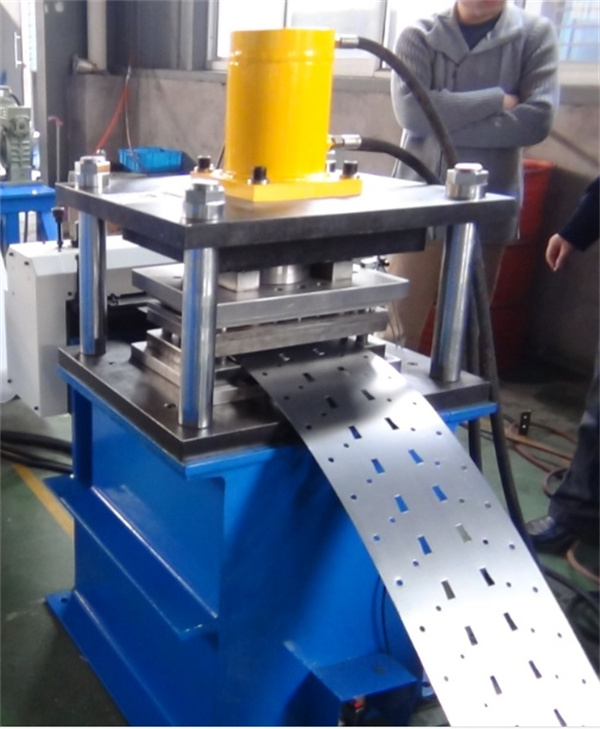

3. Servo punching mechanism:

1). Servo feeder power : 1.9 KW

2). Guiding column hydraulic punching mechanism: single station

3). Hydraulic system power : 11 KW

4). Hydraulic system with air cooling

5). Punching dies : 7 pairs (replacement of dies for different profiles)

6). Material of upper and lower template of punching mold: high-quality 45 carbon steel.

7). Material of upper and lower mold : Cr12Mov or SDK11.

8). Heat treatment hardness of upper and lower molds : HRC58-62

4. Roll Former:

1). Frame : tempering treatment after welding of high-quality steel

2). Pipe feeding frame : side hand wheel

3). Forming machine form : cast iron gearbox transmission

4). Shaft material : 40Cr quenching and tempering treatment (HB220-260)

5). Shaft diameter : Φ80 (Harbin bearing)

6). Motor power of forming machine : 18.5 KW

7). Linear speed of forming machine : 0-20 meters \ min

8). Number of forming lanes : about 18 lanes (with correction)

9). Thickness : 2-2.5mm

10). Rolled material unrolled width: see the flat chart for details (the actual test machine plate width shall prevail)

11). Length fixing : ± 1.5mm

12). Roll forming mold : 1 set (produce 7 specifications, replace looper)

13). Roll material : Gcr15 quenching treatment (HRC58-62)

14). Roll hard chromium plating : ≥ 0.05mm

15). Hydraulic station oil pump : vane pump

16). Shearing method : no waste hydraulic cutting (servo tracking)

17). Shear mold : 7 sets (blades need to be replaced when producing different specifications)

18). Molding and cutting mold material : Cr12M0V

19). Shear blade heat treatment : quenching treatment (HRC58-62)

20). Servo motor power : 3 KW

21). Hydraulic station : single circuit

22). Hydraulic system power : 7.5 KW

23). Hydraulic station oil pump : vane pump

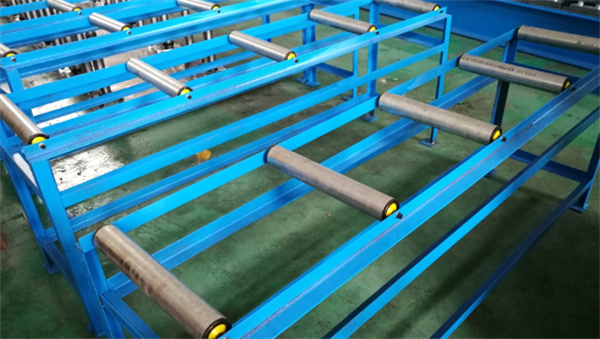

5. Unloading table:

Structure of receiving roller : Angle welding, drum type (no power)

Receiving roller material size : 1500mm x 2pcs

IV、Equipment structure:

The main machine is composed of Uncoiler, Roll forming (including Leveler, hydraulic cutting and unloading table), hydraulic system, electric control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 2-2.5mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 4 T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |