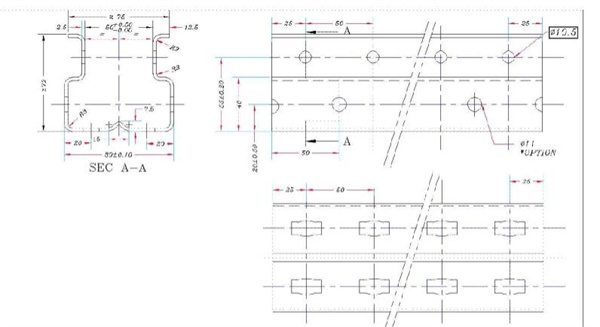

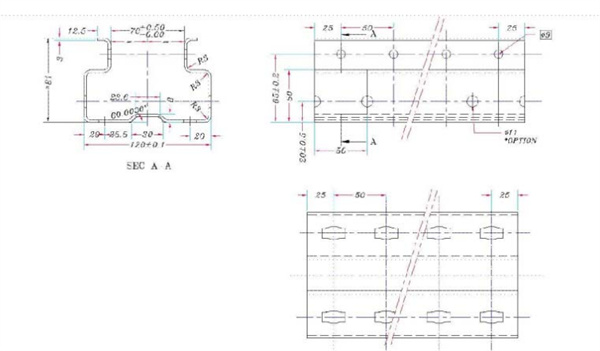

I. Profile drawings: (according to confirmation by both parties

Profile – 1:

Profile – 2:

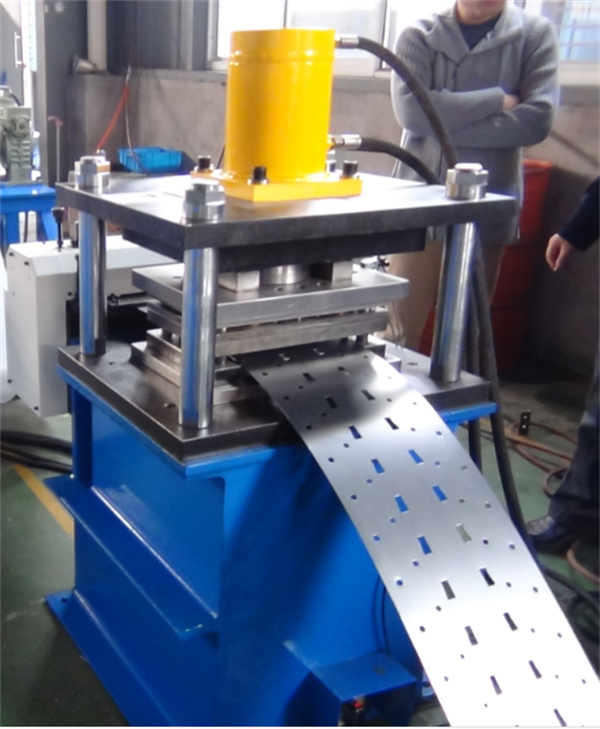

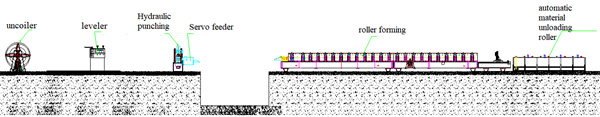

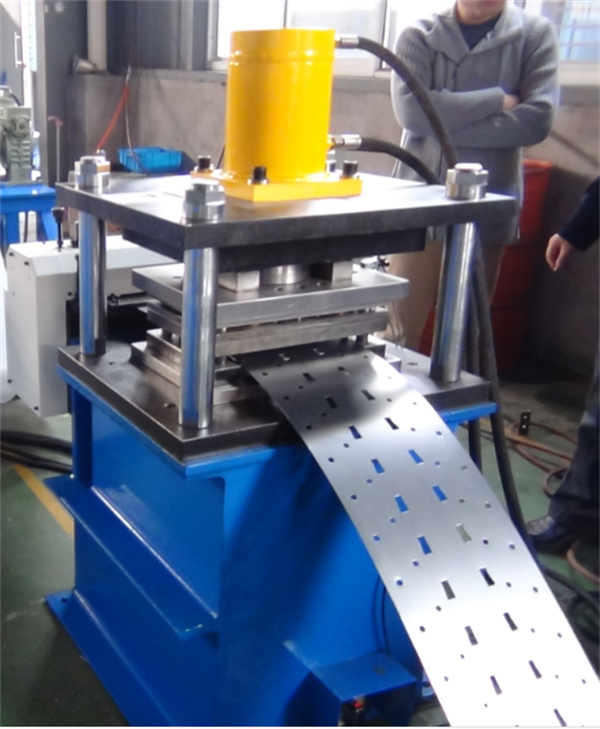

II. Process flow:

Automatic unwinding ----> Pinching and Leveling ----> Hydraulic punching (servo) ----> Roll forming -----> Fixed-length cutting (servo tracking) -----> Unloading table.

III. Main Component Data:

1. Uncoiler:

1) Automatic uncoiler : Hydraulic expanding

2) Loading weight : 4 T

3) Uncoiler coil ID : 508 mm

4) Uncoiler coil range : φ450-540 mm

5) Hydraulic power : 2.2 KW

6) Hydraulic oil pump : Gear pump or vane pump

7) Uncoiler electrical control system : the main electrical components use

2. Feeder & Leveler:

1) Two-roller pinch, seven-roller leveling

2) Leveling roller diameter : about 90mm

3) Leveling roller material : high quality 40Cr

4) Flattening shaft heat treatment method : surface high frequency quenching treatment

5) Leveling machine motor power : 3 KW

6) Reducer : worm gear

3. Servo punching mechanism:

1) Servo feeder power : 1.9 KW

2) Guide column hydraulic punching mechanism : single station

3) Hydraulic system power : 11 KW

4) Hydraulic system with air cooling

5) Punching mold : 2 Sets (by changing the mold when producing different figure profiles)

6) Punching mold upper and lower template material : high quality 45 carbon steel

7) Upper and lower mold material : Cr12Mov or SDK11

8) Upper and lower mold heat treatment hardness : HRC58-62

4. Roll Former:

1) Frame : high quality steel after welding and tempering

2) Pinch rolls feeding rack type : Side hand wheel type

3) Forming machine type : wallboard chain transmission

4) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

5) Shaft diameter : Φ80 (Harbin Bearing)

6) Molding machine motor power : 18.5 KW

7) Molding machine line speed : 0-20 m\min

8) Number of molding channels : about 18 or so (with correction)

9) Rolling thickness : 1.8-3 mm

10) Expanded width of rolled material : See the shape chart for details (based on the actual test plate width)

11) Length limit : ±1.5 mm

12) Roll forming die : 1 set

13) Roll material : Gcr15 quenching treatment (HRC58-62)

14) Roll hard chrome plating ≥ 0.05mm

15) Hydraulic station oil pump : vane pump or plunger pump

16) Shearing method : hydraulic cutting (servo tracking) – No Scrap

17) Cutting mold : 2 Sets

18) Molding shear mold material : Cr12M0V

19) Shearing blade heat treatment method: quenching treatment (HRC58-62)

20 Servo motor power : 4.4 KW

21) Hydraulic station : single circuit

22) Hydraulic system power : 7.5 KW

23) Hydraulic station oil pump : vane pump

24) Feed roller structure : square tube welding

25) Feed roller specification : 8000 mm

26) Transmission mode : chain drive

27) Motor power : 1.5 KW inverter motor

IV、Equipment structure:

The main machine is composed of Uncoiler, Pinch Leveler, hydraulic punching (servo tracking), Roll forming, Hydraulic Shear, unloading table, hydraulic system, electric control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.8-3mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 4 T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |