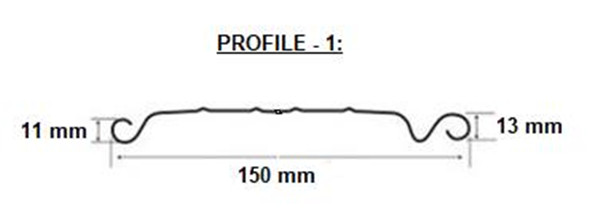

I. Profile drawings: (according to confirmation by both parties)

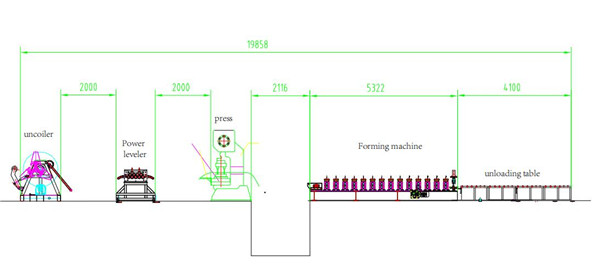

II. Process flow:

Passive feeding frame → power leveling pinch feeding device → CN servo feeding∮45T pneumatic punch → buffer induction frame → roll forming machine (with circulating cooling system) → mechanical tracking and cutting system → unloading

III. Components of the Machine Line:

1. Cantilever internal support type feeding frame:

1) Uncoiler: Passive feeding, manual expansion

2) Uncoiler Coil I.D.: Ø508 ± 30 mm

3) Feeding width: 350mm

4) Coil Max O.D.: Ø1500 mm

5) Max loading: 3 T

2. Power leveler:

1) Leveling roll quantity : 7 rolls

2) Material : 40Gr fine car

3) Leveling effective width : ≥ 300mm.

4) Max leveling speed : 0-15 m/min.

5) Leveling power : 3 KW.

6) Auto induction line speed.

3. Punching system:

(1) Servo feeder

A. Servo feeder mode : NCF - 200

B. Feeding width : ≤ 300mm

C. Feeding speed: 0-15m/min

D. Servo power: 1.3 KW

(2) 45T punch press :5 m/min.

(3) Mould material and process:

1) Punching hole mould,

2) Material: Cr12MoV

4. Roll Former:

(1) Main frame: H-beam integral welding, Mounting surface integral CNC planer

(2) Forming machine type: Wall plate chain and motor reducer drive

(3) Motor power : 5.5 KW-4P

(4) Roller way nos :15 nos.(including 1 embossing)

(5) Forming speed : 0-15m/min

(6) Material : Galvanized Steel / MS

(7) Thickness : (0.8-1.5) mm (max)

(8) Roll material : Bearing steel GCr15

(9) Shaft diamet : Φ70mm (HRB Bearing), Material: 40cr

(10) Wallboard material : A3, CNC finishing.

(11) Bearing block: cast iron, finishing

5. Hydraulic Shear:

(Tracking no stop hydraulic punching hydraulic punching and cutting)

(1) Cutting type: Hydraulic punching and cutting

(2) Forming cut type material : Cr12

(3) Heat treatment of cut blade : quenching treatment (HRC58-62)

(4) Hydraulic system power : 5.5 KW

6. Unloading table:

1. Material receiving roller structure: square tube welding, drum type (no power)

2. Specification of material receiving roller: 2000mm x 2 pieces

IV. Finished product:

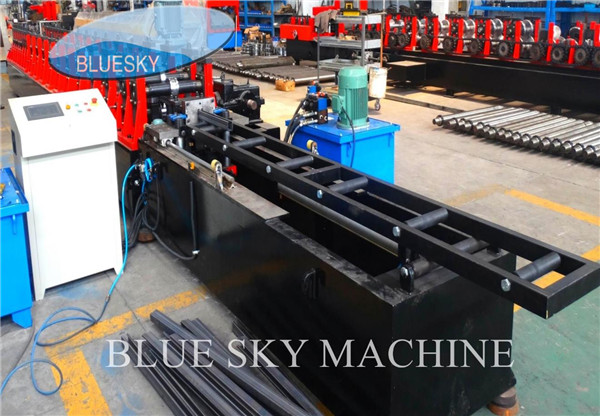

V. Machine Picture: (just for your reference)

| Raw Material | Type | Galvanized Sheet/ MS |

| Thickness | 0.8-1.5mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Manual expansion |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic punching and cutting |

| Cutter Material | Cr12 |