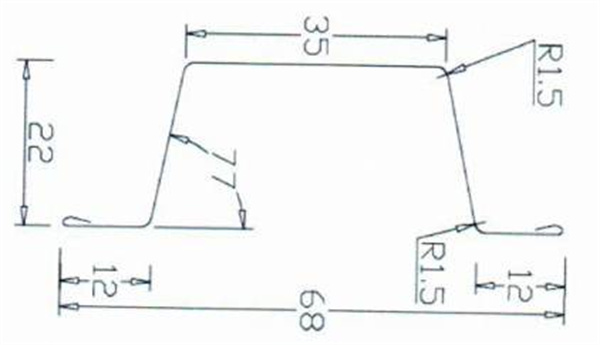

I. Profile drawing: (according to confirmation by both parties)

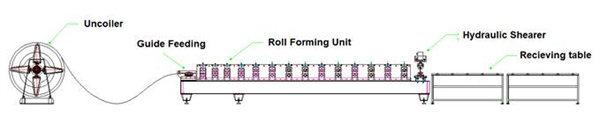

II. Process flow:

Passive uncoiling -----> Guide Feeding -----> Roll forming -----> Hydraulic Shearing -----> Discharge table.

III. Main Component Data:

1) Material : Galvanized plate

2) Material thickness range : 0.3-1.0mm

3) Product cutting accuracy : ≤±2mm

4) Machine occupied area : about 12m*2m*3m (L*W*H)

5) Voltage : 380V, 50Hz, 3 phase

IV. Machine component details:

| S No | Name | Technical data | Qty. |

| 1 | 1T manual uncoiler | 1. Material thickness: 0.1-2mm

2. Material width: 20-350mm 3. Rated loading capacity: 1 T [Max. loading capacity 1.5 T] 4. Coil ID: 508mm Coil OD: 1350mm 5. Expanding way: manual expanding |

1 nos. |

| 2 | Roll forming machine | 1. Main shaft: Φ50mm, 40Cr, lower shaft drive

2. Roller way nos.: 14 Frame: guide pillar & plate type 3. Rolling speed: 0-70m/min 4. Motor: 11KW, 4 stages, 1 nos. 5. Transmission: worm gear reducer |

1 nos. |

| 3 | Follow shearer | 1. Shearing method: hydraulic shearing

2. control method: servo follow, numerical length control |

1 nos. |

| 4 | Computer control system | 1. Frequency converter

2. PLC: 3. Encoder: 4. Touch screen |

1 nos. |

1. Manual Uncoiler:

1) Rated loading weight : 1 T

2) Coil ID : 350 - 510mm.

3) Coil OD : 1350mm.

4) Max. Coil width : 350mm.

5) Frame : steel plate & profile steel welded.

6) Function : to load and uncoiling coil, expanding by screw rod.

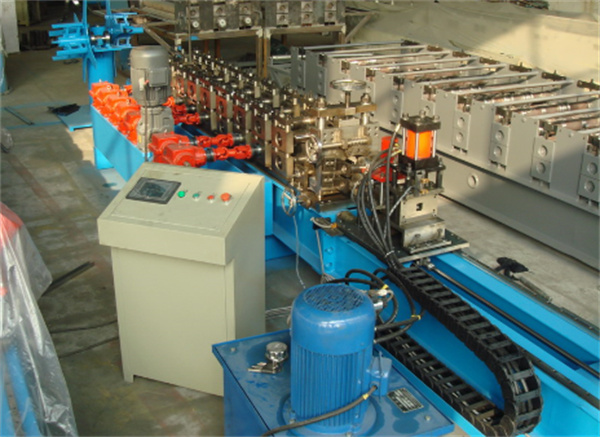

2. Roll forming machine:

1) Roll forming speed : 0-70m/min (including shearing speed)

2) Roller way nos. : 14

3) Shaft diameter : Φ50mm

4) Roller material : Cr 12, vacuum heat treatment HRC 58-62,

service life up to 2,000,000m.

5) Shaft material : 40Cr

6) Main motor : 11KW motor (4 stages), 1 nos.

7) Transmission : worm gear reducer

3. Hydraulic shearer:

Shearing by hydraulic system, put behind roll forming machine. Numerical length control by rotary encoder, and cutting length can be set. The blade made of high quality Cr12MoV, incision without burr and very small deformation, can be used for 300,000 times.

4. Unloading table:

1. Material receiving roller table structure: angle iron welding, roller

type (no power).

2. Specification of receiving roller table: 2000mm * 2 pieces.

V. Equipment structure composition:

The equipment host is composed of passive unwinding machine, roll forming host (including guided feeding, hydraulic cutting mechanism), discharging platform, hydraulic system, electronic control system, etc.

The processing of equipment roll parts is completed by processing machinery such as CNC lathes, which effectively guarantees the machining accuracy of parts and components, and uses various process equipment and testing equipment to ensure the equipment assembly accuracy.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.3-0.8mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |