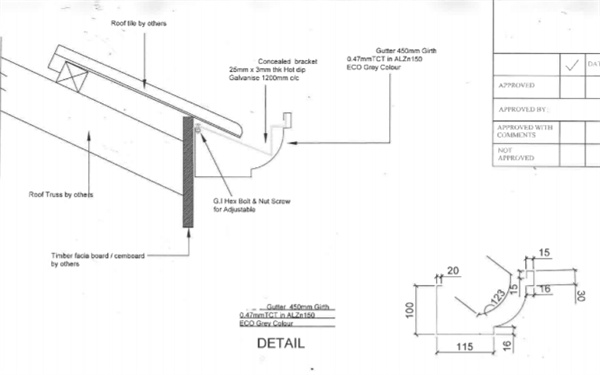

I. Profile drawing: (according to confirmation by both parties)

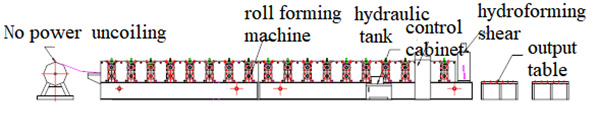

II. Process flow:

Manual Decoiler —> Manual Feeding —> Roll forming ----> Hydraulic cutting —> Output table

III. Main Component Data:

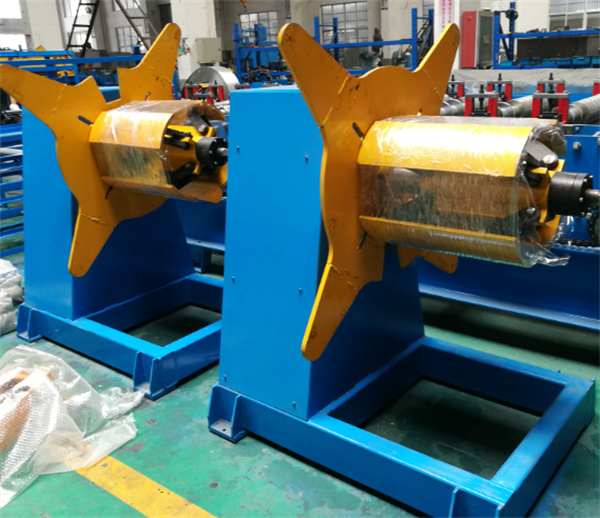

1) De-Coiler : Manual expansion and relaxation

2) Coil weight (Max) : 3 T

3) Coil Width (Max.) : 500mm

4) Motor power : 5.5kw made in China

5) Roll forming number : 18 stations

6) Machine motor power : 5.5KW

7) Material thickness : 0.4-0.8mm PPGI, PPGL, GI

8) Roller material : GCr12

9) Working speed :12-15m/min does not include shutdown cutting time

10) Shaft material : 45#, diameter 70mm

11) One-inch chain single arm drive. Bearing HRB

12) Cutting method : hydraulic cutting

13) Shear mold material : GCr12, quenching HRC58-62

14) Shear length error : +/-1.5mm

15) Hydraulic station power : 4 KW

16) Structure of receiving roller : Angle welding, drum type (no power)

17) Material receiving roller size : 2200mm x 2pcs

18) Touch screen size : 7 inches

19) Electrical requirements : 415V, 50Hz, 3-Phase

20) Body with safety cover

21) Body structure : wall plate chain surface hard chrome

Machine picture: (only for your reference)

| Raw Material | Type | Galvanized Sheet, PPGI, PPGL |

| Thickness | 0.4-0.8mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Manual expansion |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 18 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |