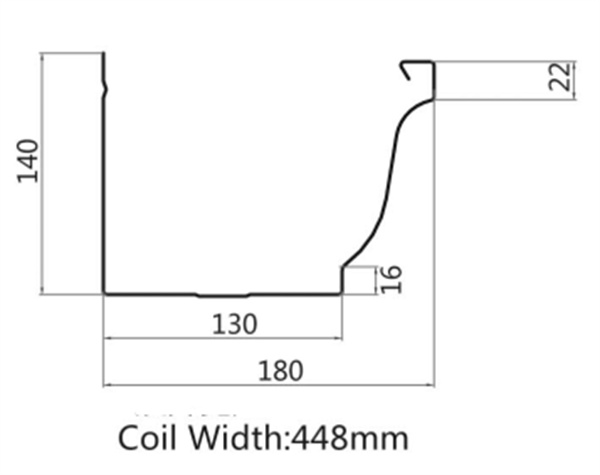

I. Profile drawing: (according to confirmation by both parties)

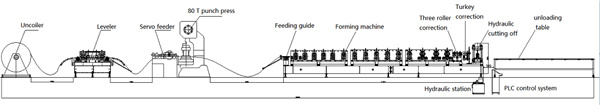

II. Process flow:

II. Process flow:

Passive unloading -----> Guide feeding ----> Roll forming ----> Cut to size

-----> Discharge table.

III. Main Component Data:

1) Uncoiler (3 T):

a) Uncoiler : Passive unwinding, manual tightening

b) Uncoiler load : 3T

c) Inner diameter of uncoiler : 508mm

d) Support range : Φ450-Φ550mm

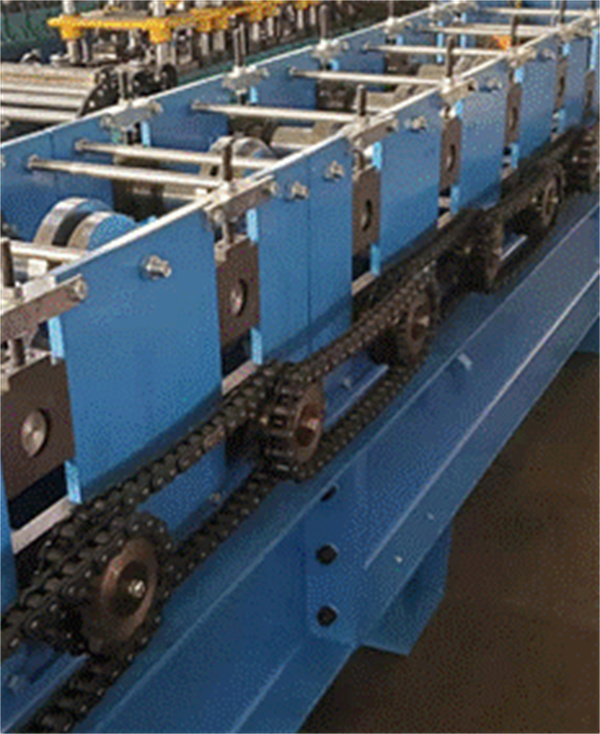

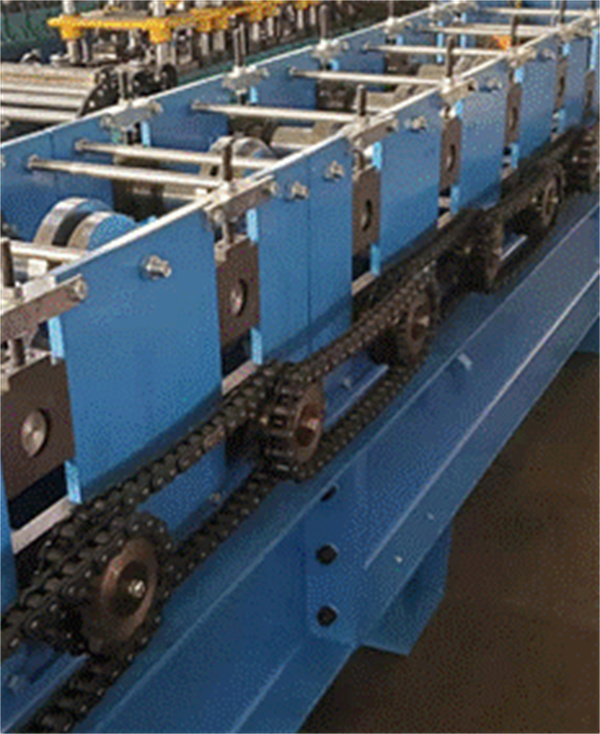

2) Forming Former:

1. Frame : tempering treatment after welding of high-quality steel

2. Forming machine form : wall plate chain drive

3. Shaft material : 40Cr quenching and tempering treatment (HB220-260)

4. Shaft diameter : Φ60 (Harbin bearing)

5. Motor power of forming machine : 7.5KW (hard gear reducer)

6. Linear speed of forming machine : 0-20 meters \ min

7. Number of molding lanes : 18

8. Thickness : 0.4-0.8mm (galvanized sheet, galvanized color steel sheet)

9. Unrolled width of rolled material : the actual test machine width

10. Length fixing : ± 1.5mm

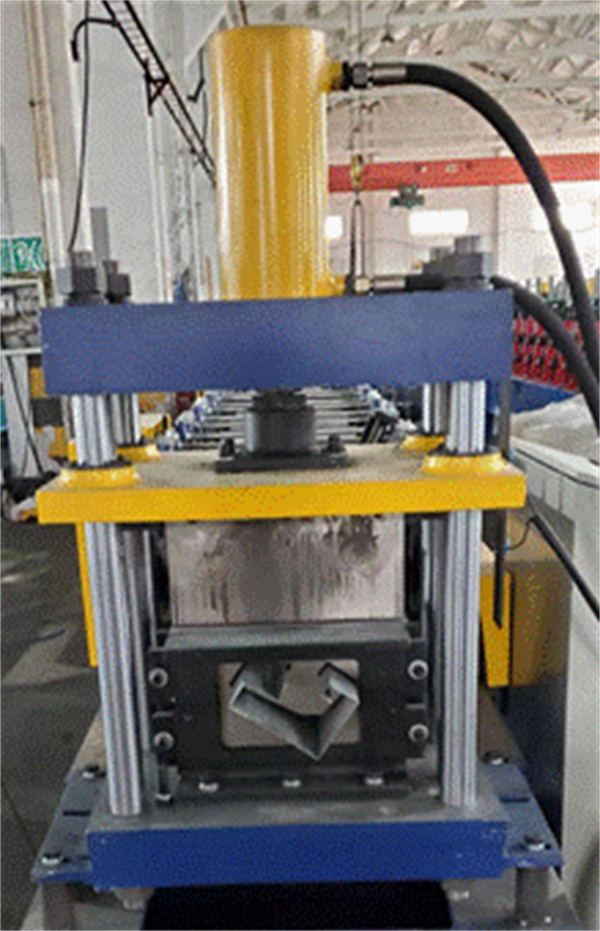

3) Hydraulic Cutting:

1. Shearing method : hydraulic cutting after forming

2. Shear blade : 1 pair

3. Molding and cutting mold material : Cr12M0V

4. Shear blade heat treatment : quenching treatment (HRC58-62)

5. Power of hydraulic system : 4KW

7. Hydraulic station oil pump : vane pump

4) Unloading table:

1. Specification of Unloading table: 1500mm x 2 pieces (to meet the

maximum specifications of profiles)

2. Unloading table structure: roller structure, square tube welding, no power

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.4-0.8mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |