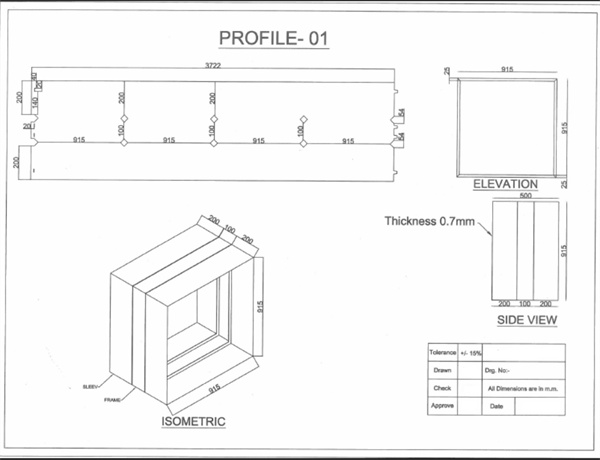

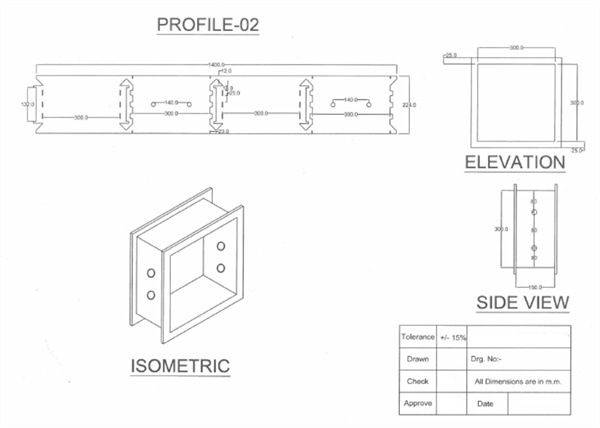

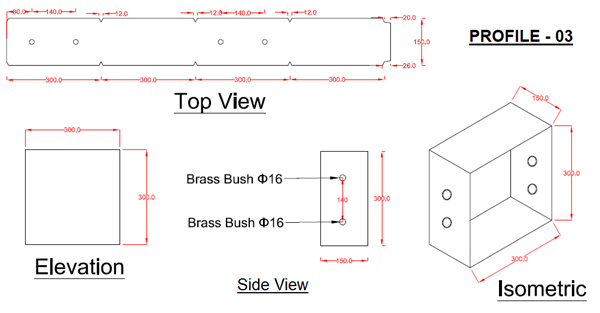

I. Profile drawing: (according to confirmation by both parties)

II. Process flow:

Passive uncoiling → Guide feed → Hydraulic punch hole (2 stations) → Roll forming → Cut off bending (2 stations) → Unloading

III. Components of the Machine Line:

1. Uncoiler:

(1) Uncoiler : Passive feeding, manual expansion

(2) Loading Weight : ≤ 5 T

(3) Uncoiler Coil I. D : 508 mm

(4) Rolling width range : (470 - 530) mm

2. Roll Former

(1) Main frame: High quality steel after welding and tempering

(2) Guide - pillar hydraulic punching mechanism: forward punch 2 stations

(3) Punching hole mould: 2 sets

(4) Punch hole mould up and down template material: high quality 45 carbon steel

(5) Up and down mould material : Cr12Mov or SDK11

(6) Up and down mould heat treatment hardness : HRC58-62

(7) Forming machine type: wall plate chain drive

(8) Shaft material : 40Cr quenching and tempering treatment

(HB220-260)

(10) Shaft diameter : Φ60 (HRB Bearing)

(11) Forming machine motor power : 7.5 KW (Hard tooth surface

reducer)

(12) Forming machine line speed : 0-5 m\min

(13) Roller way nos : 16 Nos

(14) Thickness : (0.7– 1.6) mm

(15) Expanded width of rolled material : The actual width of the

test plate shall prevail

(16) Length limit : ±1.5mm

(17) Roll forming mold : 1 set

(18) Roll material : 45# steel

(19) Hydraulic punching mechanism : back punch 2 stations

(including cutting off)

(20) Cut mold : Stop machine hydraulic cutting

(21) Bending mechanism : Hydraulic flip plate bending

after forming

(22) Hydraulic system power : 15 KW

(23) Hydraulic system cooling : Air cooling

(24) Hydraulic station pump : Vane pump or plunger pump

3. Unloading table:

(1) Structure of unloading roller : Angle welding, drum type (no power)

(2) Unloading roller material size : 1500mm * 2pcs

IV. Equipment structure:

The main machine is composed of passive uncoiler, Roll forming (including feeding, hydraulic cutting and unloading table), Hydraulic system, Electric control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.7-1.6 mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Manual expansion |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |