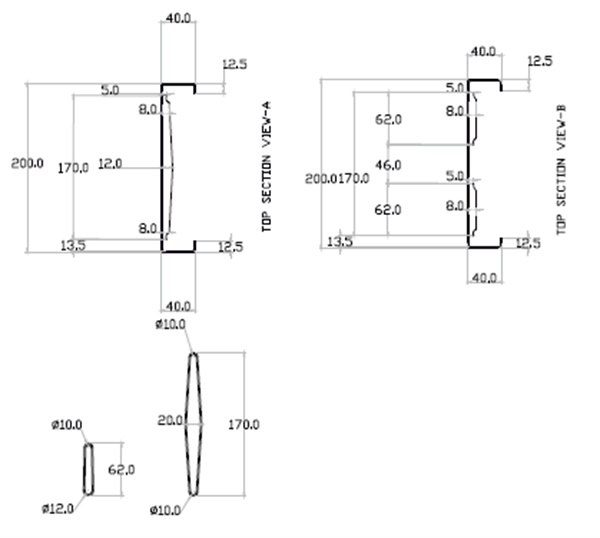

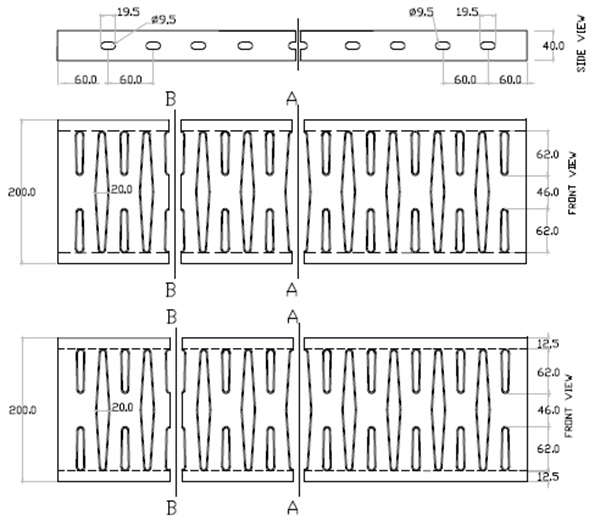

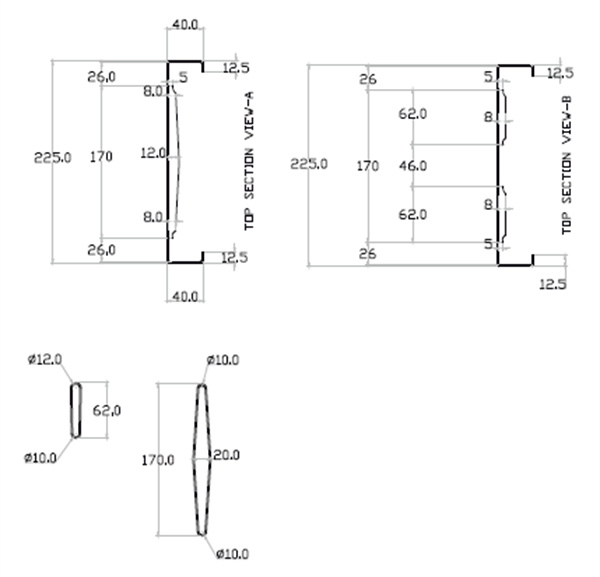

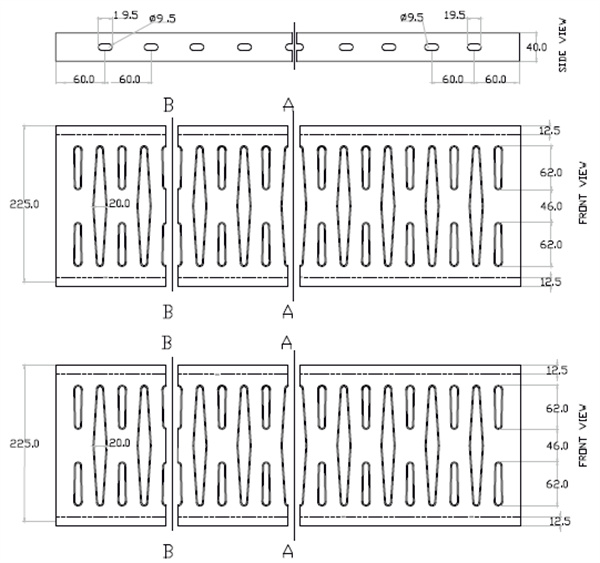

I. Profile drawings: [2 Profiles in One Machine]

Profile – 1: [LW200*40] mm

PROFILE – 2: [LW225*40] mm

PROFILE – 2: [LW225*40] mm

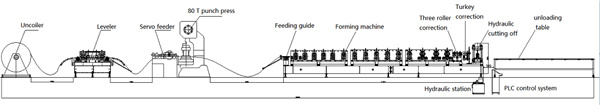

II. Process flow:

Unwinding and Leveling machine ------> Servo feeding & Punching machine (80T) -----> Roll forming ------> Hydraulic cutting (Servo tracking) ------> Discharge table.

III. Main Components of the Machine Line:

1. Uncoiling machine leveling integrated machine:

Thick material rack and leveler GH-400

| Item | Specifications | Item | Specifications |

| Material width | 400mm | Material thickness | 1.0-4.5mm |

| Reducer | 1:30 | Motor | 4 HP |

| Active press wheel | ¢95×4 | Coil inner diameter | ¢450-530mm |

| Leveling roller | ¢70×9 (up 4 down 5) | Coil outer diameter | ¢1500mm |

| Maximum load | 5 T | Feeding speed | 20m/min |

| Adjustment method | Turbine shaft | Power supply | AC three-phase 380V |

| Speed mode | Frequency | Expansion method | Hydraulic expansion |

| Loading trolley travel | 200mm | Electric machine | 50 HZ |

| Add guard; pressurized feed arm; feed port cylinder press | |||

2. Punching mechanism:

Servo feeder

Structural characteristics: driven by servo motor.

Servo motor power: 3 KW

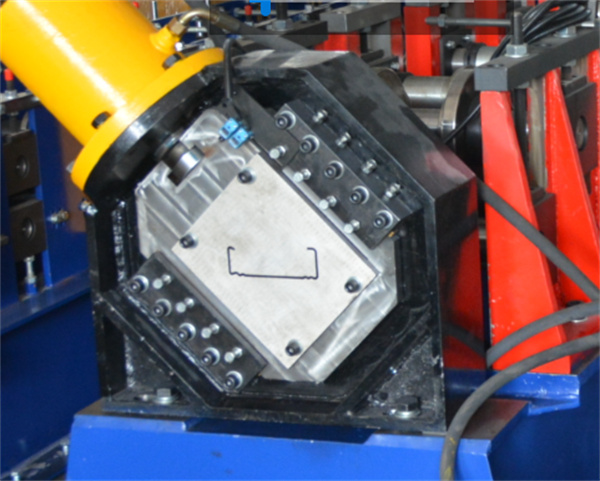

Mould

Four guide columns and ball guide columns are precisely guided.

Motherboard mould: 1 set

Punch (125T)

Punch body: It adopts steel plate welding body with good rigidity and beautiful appearance. Use combined pneumatic friction clutch.

1. Stamping machine model : JH21-125T

2. Motor power : 11 KW

3. Punch Capacity : 50 times per minute

3. Molding machine:

1. Forming machine frame : high-quality steel aging treatment after welding

2. Guided feed frame : side roller type

3. Structure of forming machine : wall plate chain transmission

4. The main motor power of the molding machine: 11 KW (hard gear reducer)

5. Line speed of forming machine : 6-8 m\min,

6. Number of forming channels : 16 channels (replace HF casing with different

specifications)

7. Shaft material : 40Cr quenching and tempering treatment (HB220-260)

8. Bearing brand : Harbin

9. Shaft diameter : Φ70mm

10. Rolling thickness : 1.5mm

12. Unfolded width of rolled material: subject to actual width of test machine plate

13. Roll material : Gcr15

14. Roll heat treatment method : quenching treatment (HRC58-62)

4. Hydraulic cutting mechanism:

1. Shearing method : hydraulic cutting after forming

2. Material of cutting blade : Cr12mov

3. Heat treatment method of shear blade: quenching treatment (HRC58-62)

4. Hydraulic system power : 5.5 KW (single circuit)

5. Hydraulic system with air cooling

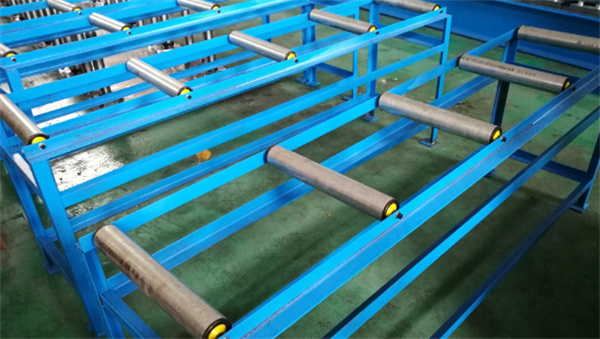

5. Unloading table:

Structure of Unloading roller : Angle welding, drum type (no power)

Unloading roller material size : 2000mm * 2pcs

V. Equipment structure:

The equipment is composed of hydraulic decoiler, cold bending and forming machine (guide feed mechanism, pinch leveling mechanism, hydraulic punching mechanism, hydraulic cutting mechanism), receiving roller table, hydraulic system and electronic control system.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1--4.5mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |