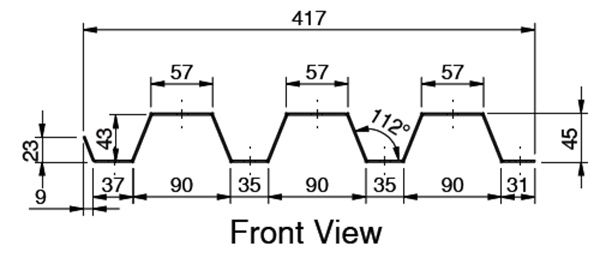

I. Profile drawing: (according to confirmation by both parties)

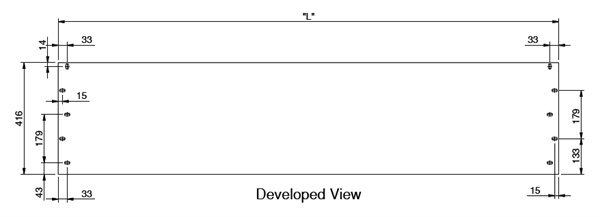

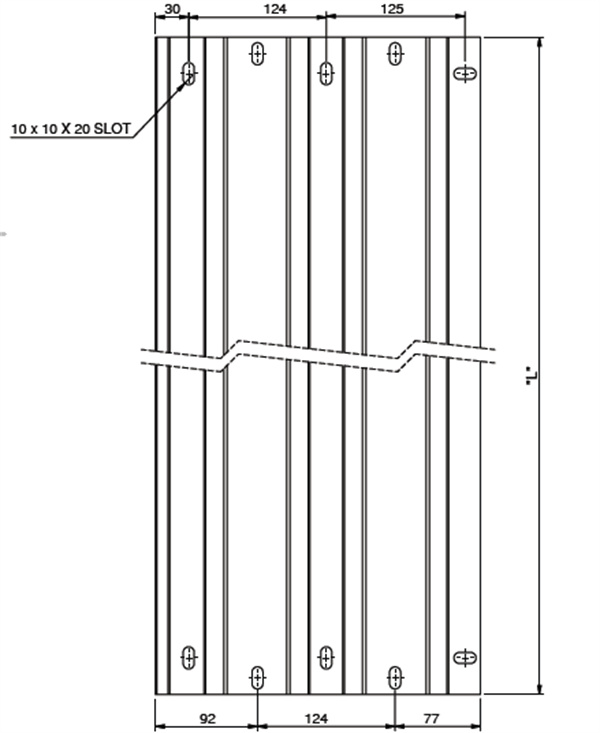

Punching Details for the profile are given as below:

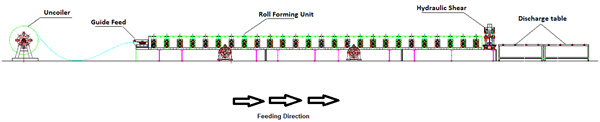

II. Process flow:

Passive Uncoiling → Guide Feeding → Roll forming → Hydraulic Shear → Discharge table.

III. Main Components of the Machine line:

1. Uncoiler:

1) Uncoiler type : Passive unwinding, Manual expanding,

2) Uncoiler Capacity : 5 T

3) Feeding Width : ≤ 1100 mm

4) Uncoiler coil ID : 508 mm

2. Roll Former:

1) Main frame: High quality steel after welding and tempering.

2) Feeding guide type : side roller

3) Forming machine type : wall-plate type, double row chain drive

(1.2 inch double row)

4) Guiding Feeding frame : Side hand wheel type

5) Shaft Material: 40 Cr Quenching and tempering treatment (HB220– 260)

6) Shaft diameter: Φ105 quenching and tempering treatment (Harbin Bearing)

7) Forming machine motor power : 2 * 18.5 KW

8) Forming machine speed : 0-20 m/min

9) Roll forming stations : 26 Stations

10) Thickness : (1.6 - 2) mm (Galvanized Sheet)

11) Material : Galvanized Sheet

12) Yield Strength : 350 MPa

13) Cut length : ±1.5 mm

14) Roller material : Gcr15 quenching treatment (HRC58-62)

15) Roller hard chromium coating : ≥ 0.05 mm

3. Hydraulic Punching & Cutting Mechanism:

1) Shearing method: Hydraulic punching and cutting to length after forming

2) Shearing blade material : Cr12M0V

3) Heat treatment method of shear blade: Quenching treatment (HRC58-62)

4) Punching mold: 1 set of head and tail (four guide pillars and ball guide pillars are accurately guided, the upper and lower mold bases are high-quality 45#, all stripper plates, lower templates, and punch inserts are imported SKD11, and other templates are Cr12MoV)

5) Hydraulic unit motor : 11 KW

6) Hydraulic oil pump : vane pump or plunger pump

4. Unloading table:

(1) Unloading table size : 2000mm x 2 pcs

(2) Unloading table structure : Roller structure, angle steel welding, no power.

Machine picture: (only for your reference)

V. Equipment structure:

The main machine is composed of uncoiler, roller forming (Including guide feed, Hydraulic cutting, and unloading table), hydraulic system, electronic control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.6-2mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 26 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |