I. Profile drawing: (according to confirmation by both parties)

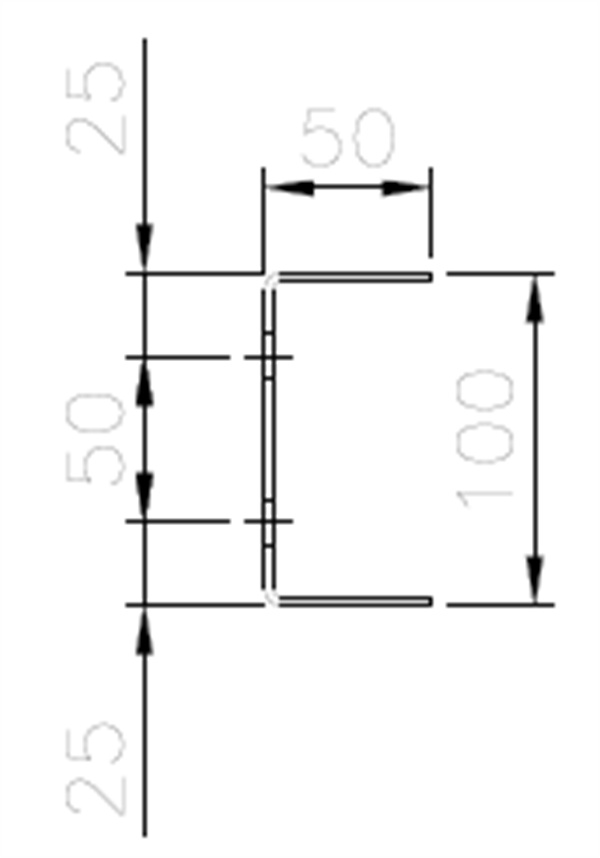

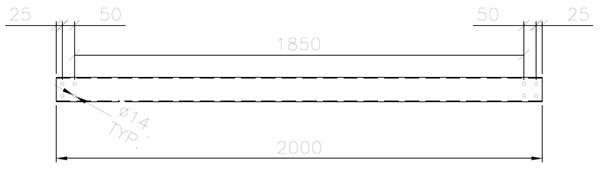

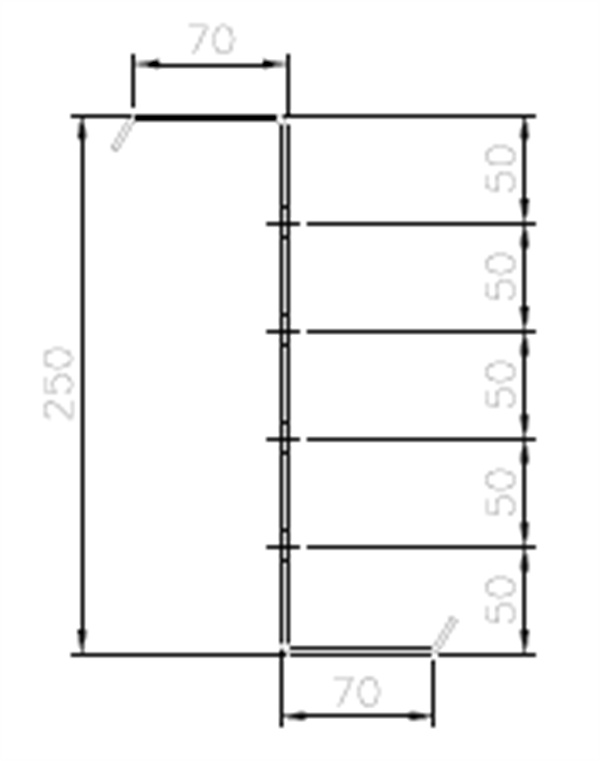

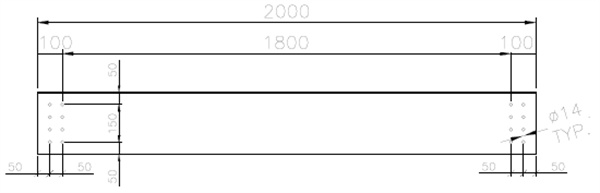

Profile-1: “C” Purlin with punching details:

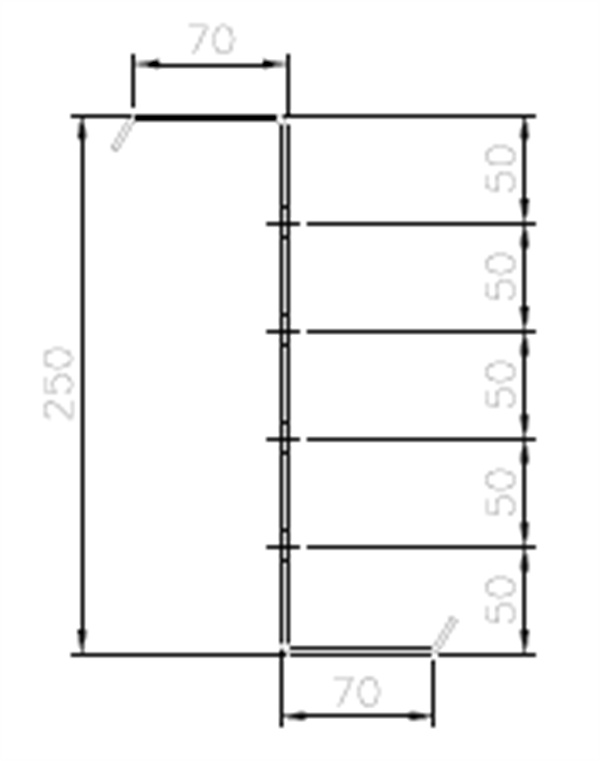

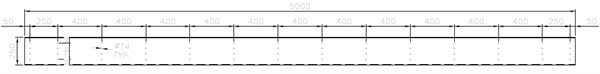

Profile-2: “Z” Purlin with punching details:

Profile-3: “Z” Purlin with punching details:

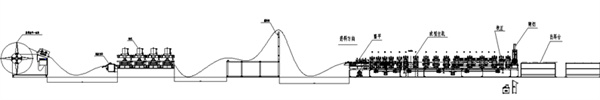

II. Process flow:

Passive Uncoiler (with levelling feeder) -----> Guide feed ------> Hydraulic Punching ------> Roll forming (including guide feed) ------> Hydraulic Shearer-----> Discharge table.

Product Specifications:

Material : Galvanized Steel ST52 (Coil)

Thickness : 1.5 mm to 3 mm

Coil Weight : 5 T (max)

Cutting Length : 1000 - 5000 mm

Rolling Speed : 15 - 20 m/min

‘C’ Purlin profile specifications:

Thickness : 1.5 mm to 3 mm

Flange Height : (50 – 80) mm

Channel Width : (100 – 300) mm

Lip Size : (15 – 20) mm

‘Z’ Purlin profile specifications:

Thickness : 1.5 mm to 3 mm

Flange : (50 – 80) mm

Height : (100 – 300) mm

Lip Size : (15 – 20) mm

Lip Radius : 135 degrees

III. Components of the Machine Line:

1. Uncoiler:

(1) Uncoiler : passive unwinding, hydraulic tensioning

(2) Unwinding machine load : 5 T

(3) Inner diameter of unwinding machine support roll: φ508mm

(4) Rolling support range : φ450 - 530mm

(5) Power of hydraulic system of unwinder : 1.5 KW

(6) Oil pump of uncoiler hydraulic system : gear pump or vane pump

(7) Leveling mechanism structure: two-roller pinch feeding, seven-roller leveling

(8) Diameter of leveling roller : about φ60mm

(9) Leveling roller material : high quality 40Cr

(10) Heat treatment method of leveling shaft: surface high frequency quenching treatment.

2. Servo punching mechanism:

(1) Specification of servo feeder : NC-300

(2) Servo feeder power : 3KW+ planetary reducer

(3) Guide column hydraulic punching mechanism: 2 stations

(4) Punching die : 2 sets

(5) Material of upper and lower template of punching die: high-quality No. 45 carbon steel

(6) Upper and lower mold material : Cr12Mov or SDK11

(7) Heat treatment hardness of upper and lower molds: HRC58-62

(8) Hydraulic system power: 22KW

(9) Cooling method of hydraulic system: air cooling

(10) Oil pump of hydraulic station: vane pump or plunger pump

3. Roll Former:

1. Frame: high-quality steel is tempered after welding

2. Forming machine form: cast iron archway chain drive

3. Shaft material : 40Cr quenching and tempering treatment (HB220-260)

4. Shaft diameter : Φ80 (Harbin Bearing)

5. Motor power of forming machine : 18.5KW

Height traverse motor power : 2 * 0.75 KW

Width traverse motor power : 1 * 1.5 KW

6. Line speed of forming machine : 0-20 m\min

7. Number of forming channels : 15 channels (excluding straightening)

8. Thickness : 1.5-3.0mm

9. Rolled material : Q235B galvanized sheet

10. Unfolded width of rolled material : subject to actual width of test machine plate

11. Length sizing : ±1.5mm

12. Roll forming mold : 1 set

13. Roll material : Gcr15 quenching treatment (HRC58-62)

14. Roll hard chrome plating : ≥ 0.05mm

4. Hydraulic Shearer:

1. Shearing method : step-less universal hydraulic cutting after forming

2. Shear blade : 1 pair

3. Material of forming and shearing mould : Cr12M0V

4. Heat treatment method of shear blade : quenching treatment (HRC58-62)

5. Hydraulic system power : 11KW (single circuit)

6. Oil pump of hydraulic station : vane pump

5. Unloading Table:

1. Material receiving roller structure: square tube welding, drum type (no power)

2. Specification of material receiving roller: 2000mm x 2 pieces

IV. Composition of equipment structure:

The main machine of the equipment is composed of a passive uncoiler, a servo punching mechanism, a roll forming machine (including guided feed and hydraulic cutting mechanism), a discharge platform, a hydraulic system, an electronic control system, etc.

Machine Picture:

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.5-3 mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | hydraulic |

| Capacity | 35T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |