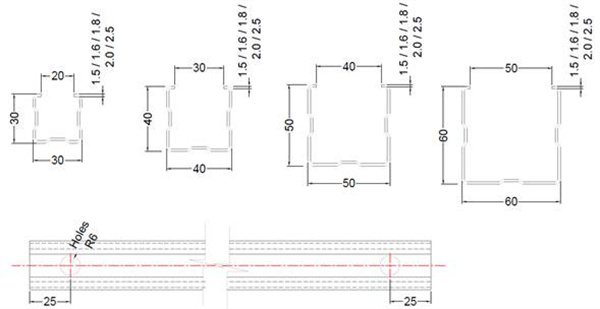

I. Profile drawings:

II. Process flow:

Passive unwinding ----> Roll forming -----> Fixed-length cutting (servo tracking) with punching -----> Discharge.

III. Main Component Data:

i. Uncoiler : passive unwinding, manual tightening

ii. Uncoiler load : 3 T

iii. Inner diameter of uncoiler : 508mm

iv. Uncoiler support roll width : ≤200mm

v. Frame : tempering treatment after welding of high-quality steel

vi. Pinch feeding frame : side roller type

vii. Forming machine form : wall plate chain drive

viii. Leveling mechanism structure : two-roll pinch, five-roll leveling

ix. Leveling shaft material : 40Cr

x. Shaft diameter of leveling shaft : about 80mm

xi. Surface treatment of leveling shaft : hard chrome plating after high frequency quenching on the surface.

xii. Motor power of forming machine : 11KW

xiii. Linear speed of forming machine : 0-18 meters \ min

xiv. Number of molding lanes : 14 (30, 40, 50/60, one out of three)

xv. Shaft material : 40Cr quenching and tempering treatment (HB220-260)

xvi. Shaft diameter : Φ80 (Harbin bearing)

xvii. Rolling thickness : 1.5-2.5mm

xviii. Rolled material unfolding width : the actual test machine plate width shall prevail

xix. Length fixing : ± 1.5mm

xx. Roll material : Gcr15 quenching treatment (HRC58-62)

xxi. Roll hard chromium coating ≥ 0.05mm

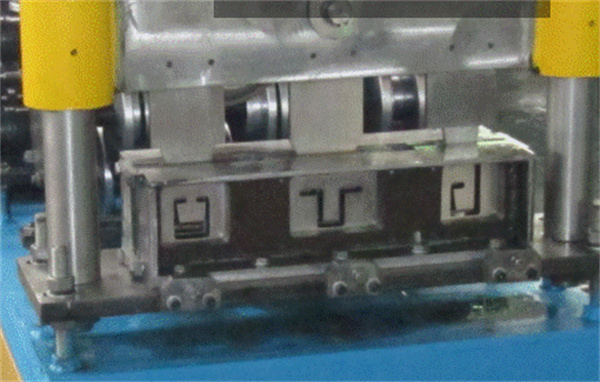

xxii. Calibration mechanism : Turkey calibration head

xxiii. Shearing method : Hydraulic punching integrated (head and tail punching and cutting at one time)

xxiv. Molding and cutting mold material : Cr12M0V

xxv. Shear blade heat treatment : quenching treatment (HRC58-62)

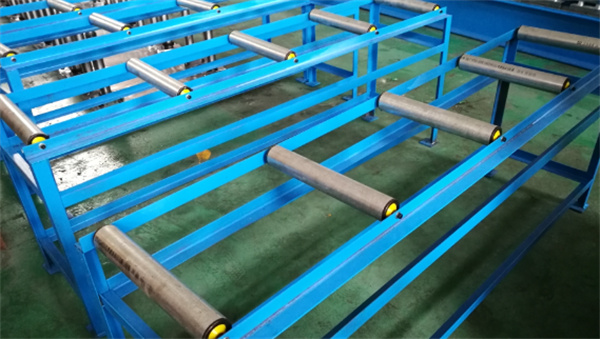

xxvi. Receiving roller structure: unpowered roller (angle welding)

xxvii. Specification of receiving roller table: 1500mm X 2 pieces

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.5-2.5mm | |

| Performance | Speed | Max. 18m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 5 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |