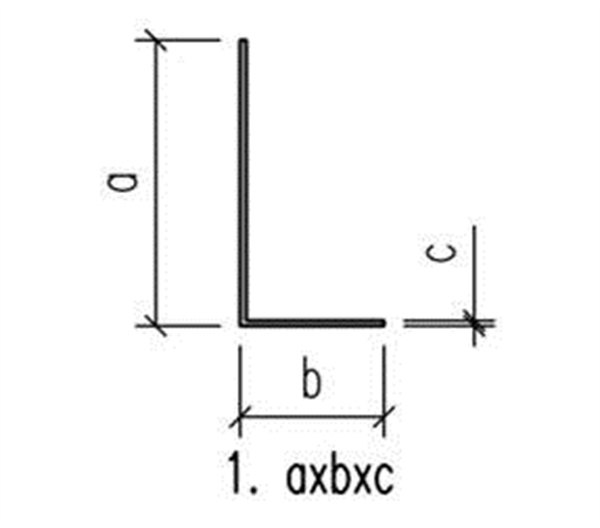

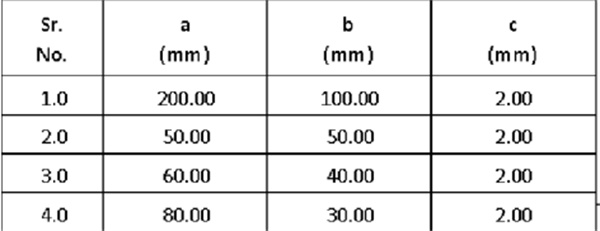

I. Profile drawing: (according to confirmation by both parties)

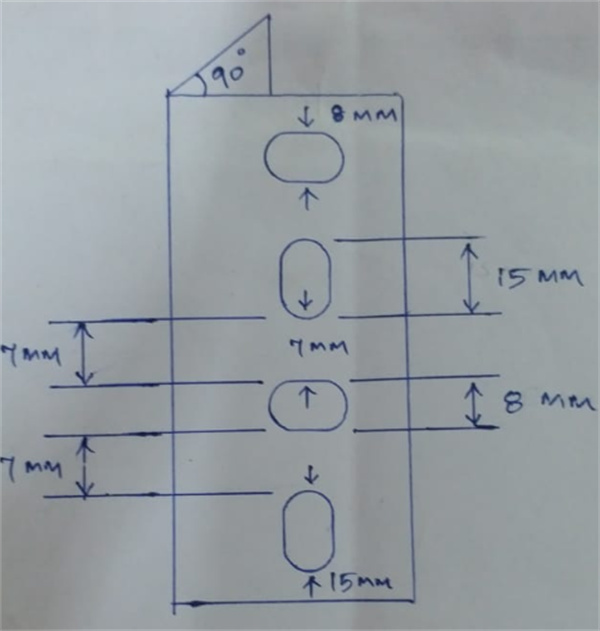

Punching Details:

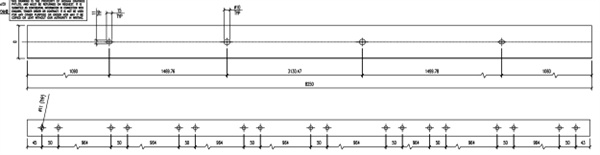

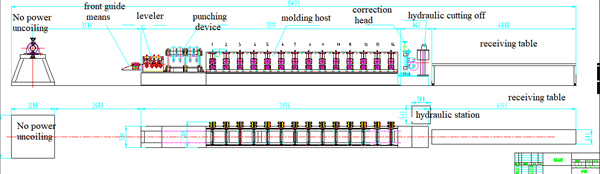

II. Process flow:

Passive uncoiling -----> Guide Feeding -----> Hydraulic Punching -----> Roll forming -----> Hydraulic Shearing -----> Discharge table.

III. Components of the Machine Line:

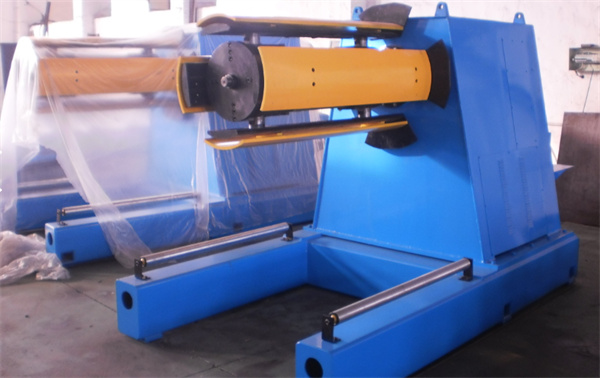

1. Uncoiler:

(1) Uncoiler : Passive uncoiler, Manual expanding,

(2) Loading Capacity : 5 T

(3) Motor power : 5.5 KW

(4) Hydraulic power : 3 KW

(5) Uncoiler coil ID : 508mm

(6) Uncoiler coil range : 450-540mm

2. Hydraulic Punching Unit:

(1) Punching mold : 2 sets

(2) Plate type specific size : in line with national construction molding plate GBT/12755-91

3. Roll Former:

(1) Frame : Tempering treatment of high quality section steel after welding.

(2) Pinch rolls feeding guide type : side roller type

(3) Forming machine type : wallboard chain transmission

(4) Wall type with chain to drive

(5) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

(6) Φ70 quenching and tempering treatment (Harbin Bearing )

(7) Forming machine motor power : 11 KW (hard surface reducer)

(8) Forming machine speed : 15-20 m/min

(9) Roll forming stations : 10 stations

(10) Rolling thickness : 2 mm

(11) Rolling Expanded material width : Based on the actual test plate width

4. Hydraulic Shearer:

(1) Hydraulic unit motor : 7.5 KW

(2) Hydraulic oil pump : Gear pump or vane pump

(3) Shearing blade material : Cr12M0V

(4) Shearing way : hydraulic shearing

(5) Cut length tolerance : ±1.5mm

(6) Heat treatment method of shear blade : Quenching treatment (HRC58-62)

5. Unloading table:

(1) Unloading table size : 2000mm x 2 pcs

(2) Unloading table structure : Roller structure, angle steel welding, no power.

(3) Voltage : 415V, 50Hz, 3phase (as per user)

| Raw Material | Type | Galvanized Sheet |

| Thickness | 2mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Manual expanding |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 10 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |