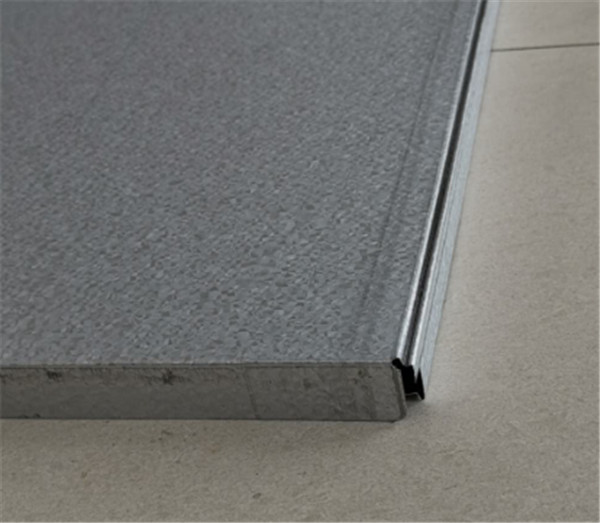

I. Profile: (according to confirmation by both parties)

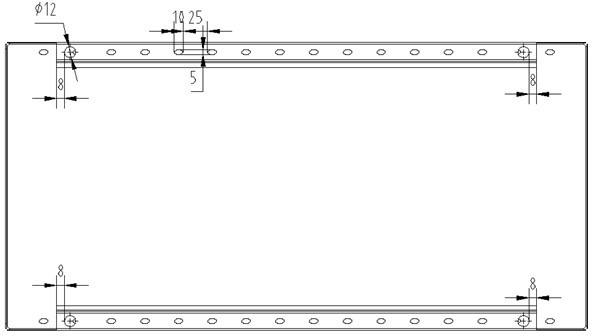

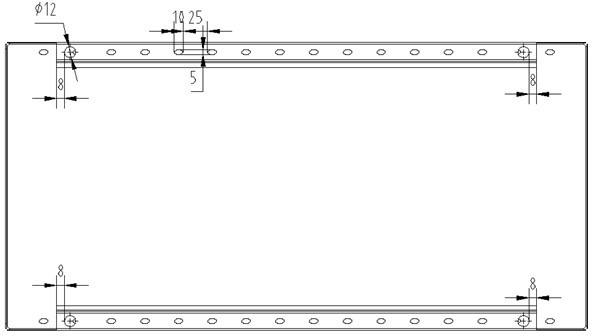

Punching Details:

II. Process flow:

5T manual decoiler -----> Lateral holes punching -----> Corner cut (42mm) -----> Corner cut (52mm) -----> Corner cut (90mm) -----> Roll Forming -----> Hydraulic cutting & bending combination mould -----> Output Discharge.

II. Machine Component details:

1. 5T Manual Decoiler:

1) Single head decoiler : hydraulic inner expansion

2) Coil weight (Max):5 T

3) Coil diameter (Max) : 1600 mm

4) Coil Width (Ma) : 800 mm

2. Guiding, 2 pinch rolls feeding and 7 rolls leveling:

1) We adopt 2 pinch rolls for feeding, rolls diameter 90mm

2) We adopt 7 rolls leveling (3 top rolls and 4 bottom rolls for leveling)

3) Pinch rolls and leveling rolls material :40Cr

4) Pinch rolls and leveling rolls width : (max) 800mm

5) Leveling motor power: 7.5 KW

3. Hydraulic punching press machine and punching moulds:

1) Hydraulic station power : 7.5 KW

2) Mould material : Cr12HRC58-62

4. Roll Former:

1) Main powr : 15KW, made in china (2 * 7.5KW)

2) Machine frame structure : Cantilever structure and the width can

be adjustable automatically.

3) Forming station: 22 or 24 Nos

4) Diameter of shaft : ¢75mm

5) Material of shaft : 45#steel

6) Thickness : 0.4--1.2mm, G350Mpa galvanized steel,

Pre-painted steel etc.

7) Material of the roller : GC15 quenched HRC58-62 ,chromed on

the surface

8) Way of cutting and bending: hydraulic post-cutting and bending combination mould.

9) Cutting power : 7.5KW

10) Cutting blade material: Cr12 HRC58-62

11) Bending mould material: Cr12,HRC58-62

12) Cutting length tolerance : +/-0.5mm

Cantilever structure:

5. Cutting & bending combination mould:

6. Unloading Tables:

To support the finished panels.

The table is 2 pcs * 2m long tables.

It is consists of sliding rolls, welded angles

The height will be designed according to the machine height

7. Hydraulic Station:

III. The components of the whole line:

5Tmanual decoiler, holes Punching & corner cut, Roll forming Machine,Hydraulic Cutting & bending mould combination, Run-out table,Electric control panel,Hydraulic system

| Raw Material | Type | Galvanized Sheet, Pre-painted steel |

| Thickness | 0.4-1.2 mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 24 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |