I. Profile drawing: (according to confirmation by both parties)

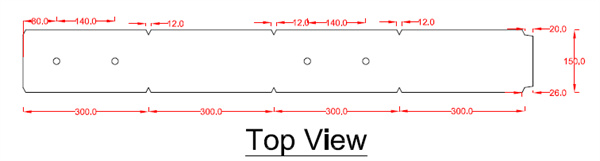

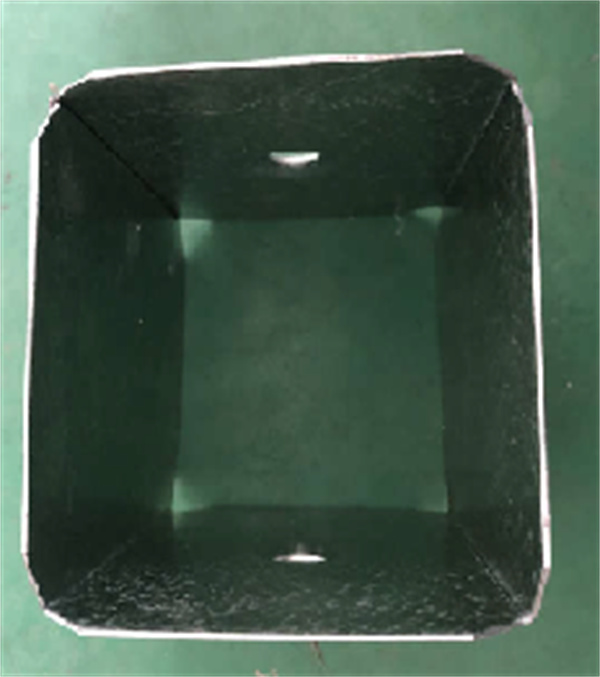

Profile – 1:

Side View

Minimum Frame Size (width*height) : (100 * 100) mm

Maximum Frame Size (width*height) : (2000 * 2000) mm

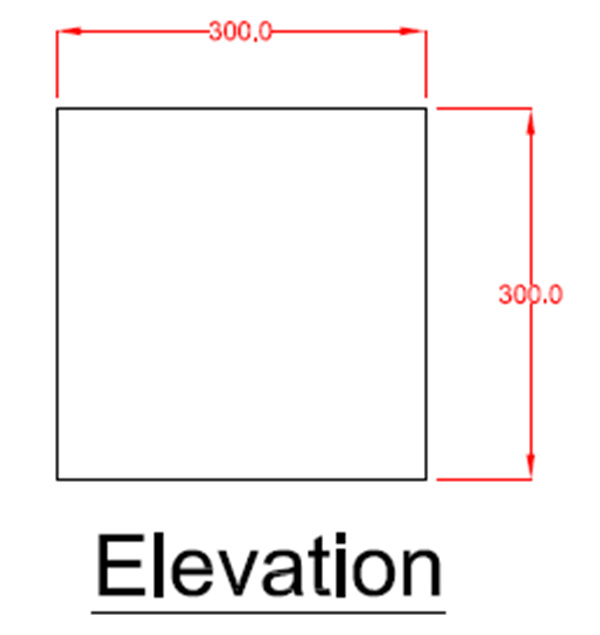

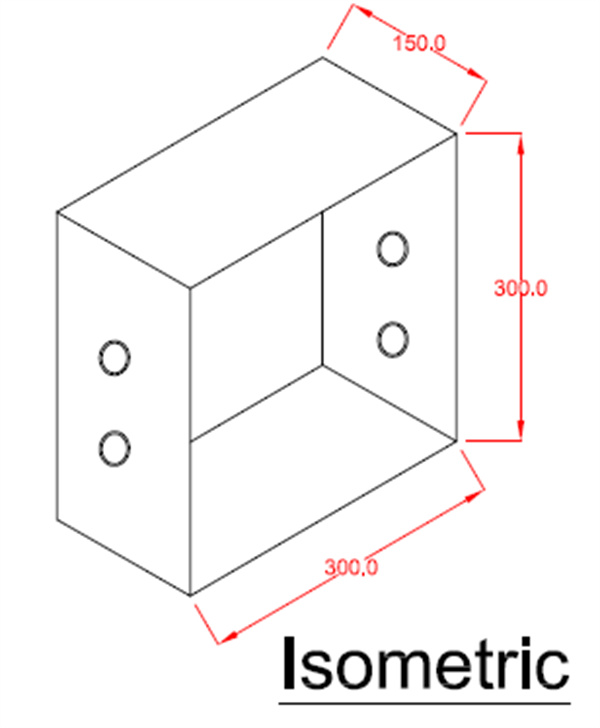

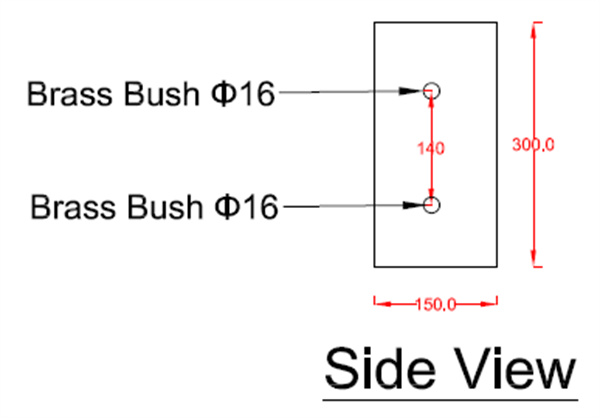

Profile – 2:

Frame Size (minimum) : (100*100) mm

Frame Size (maximum) : (600*600) mm

Length: 150 mm

II. Process flow:

Passive uncoiling → Guide feed → Hydraulic punch hole (2 stations) → Cut off bending (2 stations) → Unloading.

III. Main Components Data:

1. Uncoiler:

(1) Uncoiler : Passive feeding, manual expansion

(2) Loading Weight : ≤ 5 T

(3) Uncoiler Coil I. D : 508 mm

(4) Rolling range : (470-530) mm

2. Guide Feeder:

(1) Guide - pillar hydraulic punching mechanism: forward punch 2 stations

3. Punching Mechanism:

(2) Punching hole mould: 2 sets

(3) Punch hole mould up and down template material: high quality 45 carbon steel

(4) Up and down mould material : Cr12Mov or SDK11

(5) Up and down mould heat treatment hardness : HRC58-62

4. Bending Machine:

1) Bending mechanism : Hydraulic flip plate bending after forming

2) Hydraulic system power : 7.5 KW

3) Hydraulic system cooling : Air cooling

4) Hydraulic station pump : Vane pump or plunger pump

IV. Equipment structure:

The main machine is composed of passive uncoiler, guide feeder, punching mechanism, hydraulic cutting and bending, Hydraulic system, Electric control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.3-0.8mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Manual |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |