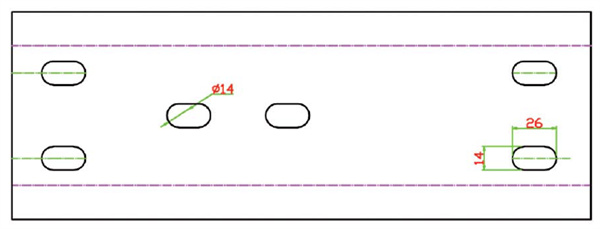

I. Profile drawing: (according to confirmation by both parties)

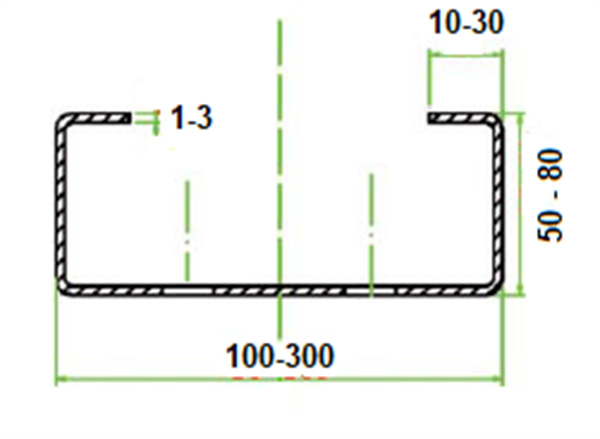

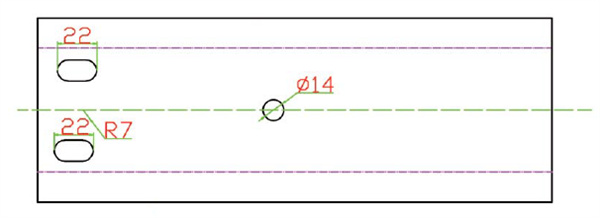

Profile-1: “C” Purlin with punching details:

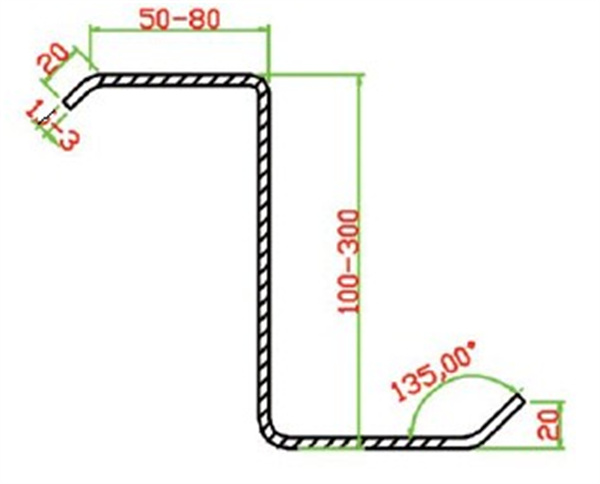

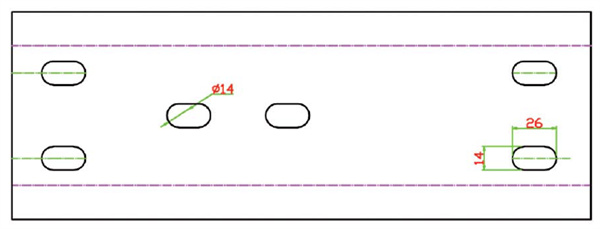

Profile-2: “Z” Purlin with punching details:

Profile-3: “Z” Purlin with punching details:

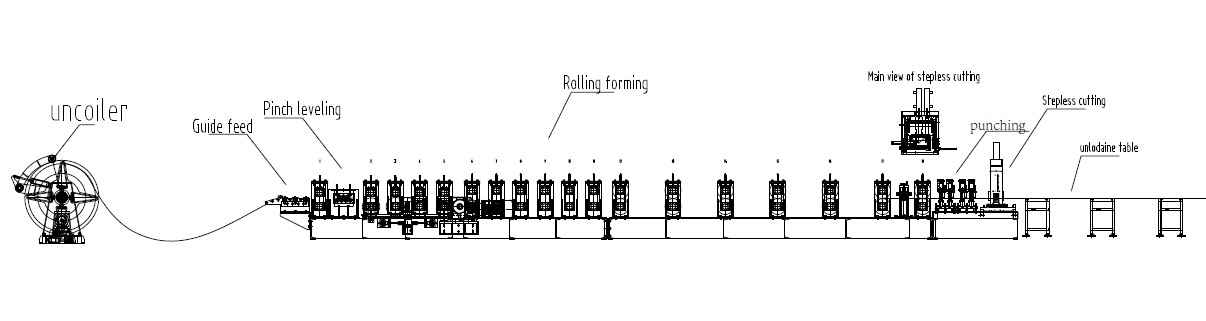

II. Process flow:

Uncoiler -----> Guide feed ------> Pinch Leveling ------> Roll forming ------> Hydraulic Punching -------> Hydraulic Shearer (Step-less cutting) -----> Discharge table.

III. Product Specifications:

Material : Galvanized Steel ST52 (Coil), CR Steel, HR Steel.

Thickness : 1.2 mm to 3 mm

Coil Weight : 5 T (max)

Cutting Length : 1000 - 5000 mm

Rolling Speed : 15 - 20 m/min

‘C’ Purlin profile specifications:

Thickness : 1.2 mm to 3 mm

Flange Height : (50 – 80) mm

Channel Width : (100 – 300) mm

Lip Size : (10 – 30) mm

‘Z’ Purlin profile specifications:

Thickness : 1.2 mm to 3 mm

Flange : (50 – 80) mm

Height : (100 – 300) mm

Lip Size : (15 – 20) mm

Lip Radius : 135 degrees

Accuracy Requirements:

Length Tolerance : ≤±1.0 mm

Width Tolerance : ≤±0.5 mm

Height Tolerance : ≤±0.5 mm

The tolerance of distance from center of last hole to profile end : ≤±1.0 mm

IV. Components of the Machine Line:

1. Uncoiler:

(1) Uncoiler : Hydraulic uncoiling, Cantilever hydraulic slider inner

expansion type.

(2) Unwinding machine load : 6 T

(3) Suitable coil width : 550 mm

(4) Suitable Coil max outer diameter : 1500 mm

(5) Rolling support range : φ480 - 520mm

(6) Specification of expansion and contraction oil cylinder: Φ100 x 100 mm

(7) Braking mode: pneumatic pressure regulating braking

2. Guide Feed:

Prevent material deviation during production.

3. Leveler:

The leveller is composed of sheet metal leading in device, guide roller, guide device adjustable on both sides, leveling roller, etc. It is driven by a single motor, which is slightly slower than the main drive motor.

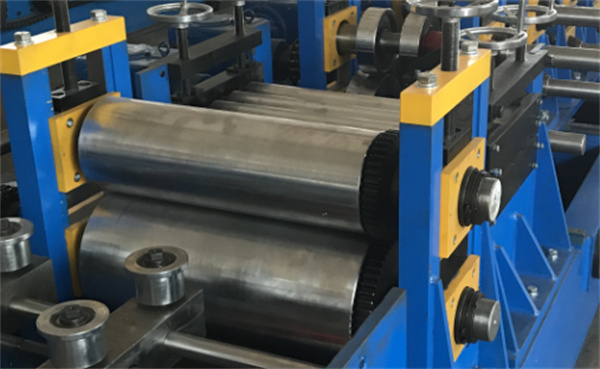

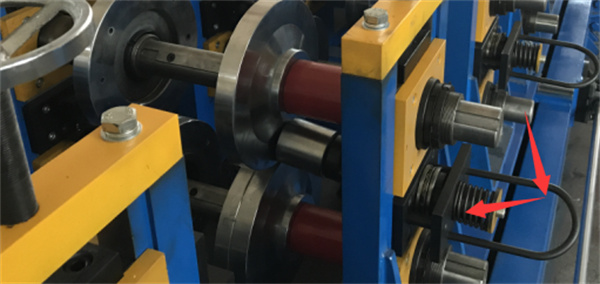

4. Roll Former (Quick change type):

The forming machine is composed of driving motor, frame, forming roller and electric regulating work piece specification device.

(1) The forming roller drive motor adopts 18.5KW hard tooth surface reducer and frequency conversion speed regulation. The chain transmission between roller channels is adopted, and the encoder controls the braking.

(2) The frame is made of channel steel as the main beam and welded with reinforcement plates in the middle.

(3) The change between CZ is completed by manual 180-degree flip (3 hand-wheel changes completed)

(4) Three-roll correction mechanism

(5) Installation form : standing house type

(6) Roller table form : split roller table on both sides and main shaft plug-in drive.

(7) Roller material : Cr12

(8) Shaft material : high quality 45 steel

(10) Shaft diameter : Φ80mm (Insert part: shaft diameter Φ60mm)

(11) Maxi forming speed of purlin : 25 m/min

(12) Main motor power : 18.5 KW

(13) Forming machine width adjusting total power: (2x0.75KW) + (1x1.5KW) = 3 KW

(14) Driving form : Chain drive

(15) Forming Roller way nos : 16 Stations

(16) Mould and cutter material : Cr12MoV quenching treatment

(17) Punching mould : 3 Sets

(18) Horizontal adjustment range of punching hole distance : 45 ~ 550mm

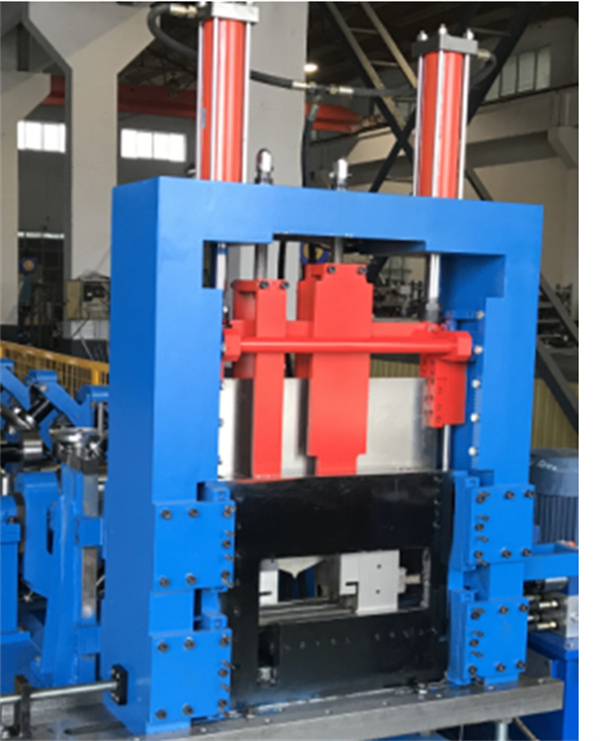

5. Hydraulic shearing mechanism:

(1) According to the length parameter of the input work piece, use the encoder to fix the length, stop and cut off,

(2) Adopt step-less adjustable cutter method. Different specifications do not need to change the die, just adjust the size of the die.

(3) Main parameters:

1) Maxi shear Steel sheet thickness : 3 mm

2) Effective cutting width of work piece : 350 mm

3) Universal Cutting combination tool : Cr12MoV

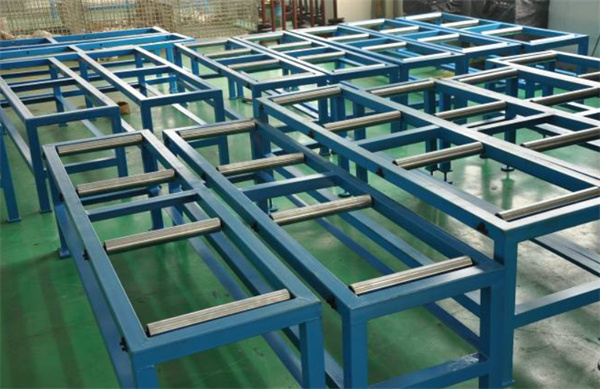

6. Unloading Table:

1. Material unloading roller structure: square tube welding, drum type (no power)

2. Specification of material unloading roller: 4000mm x 2 pieces

7) Hydraulic system:

1) Hydraulic station power : 11 KW

2) Working pressure : 20 Mpa

| Raw Material | Type | Galvanized Steel ST52 (Coil), CR Steel, HR Steel |

| Thickness | 1.2-3mm | |

| Performance | Speed | Max. 25m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |