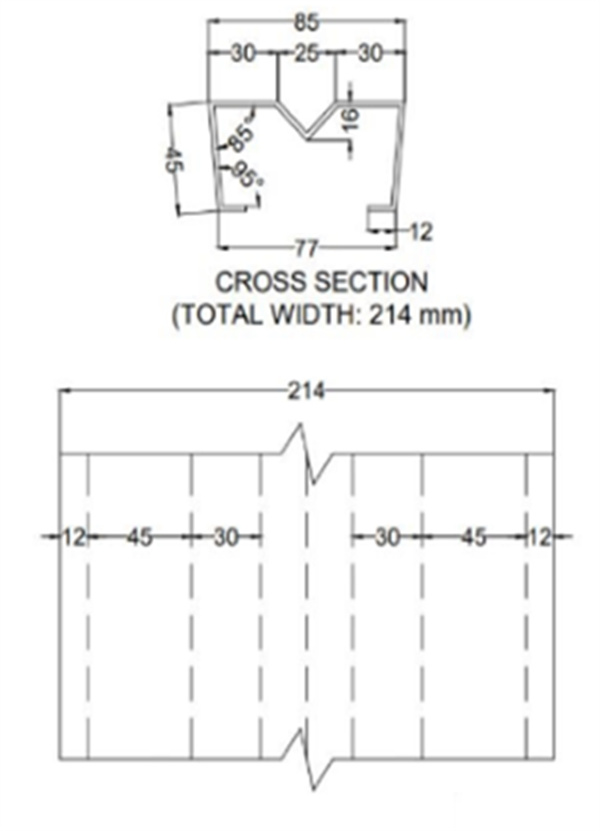

I. Profile drawing: (according to confirmation by both parties)

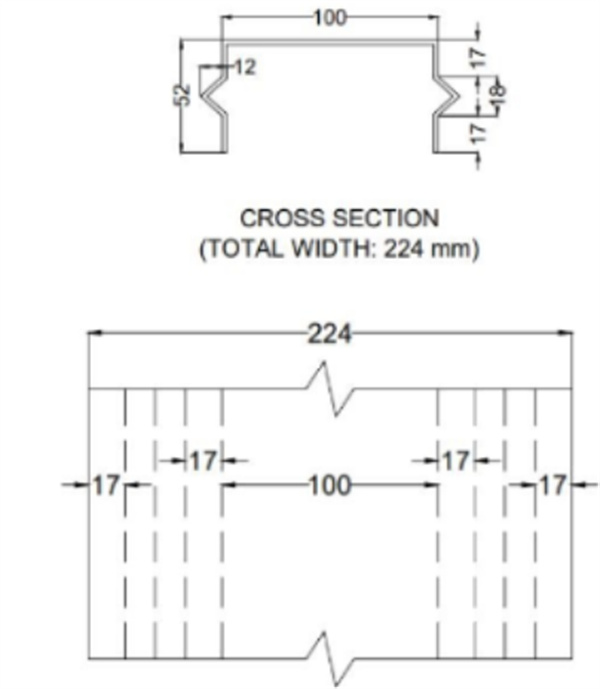

II. Process flow:

Passive uncoiling → Guide Feeding → Forming machine → Hydraulic cutting → unloading

III. Machine Component details:

1. Uncoiler:

1) Uncoiler : Passive feeding, Manual expansion

2) Loading Weight : 4 T

3) Uncoiler Coil I. D : 508mm

4) Rolling range :450-540mm

2. Roll Fomer

(1) Main frame : High quality steel after welding and tempering

(2) Pinch Feeding frame type : Side roller type

(3) 2 roller pinch, 7 roller leveling

(4) Leveling roller diameter : about 70mm

(5) Leveling roller material : high quality 40Cr

(6) Leveling shaft heat treatment type : surface high frequency quenching treatment

(7) Forming machine type : wall plate chain drive

(8) Shaft material: 40Cr quenching and tempering treatment (HB220-260)

(9) Shaft diameter: Φ75 (HRB Bearing)

(10) Forming machine motor power: 11KW (Hardened surface reducer)

(11) Forming machine line speed: 0-15 m\min (excluding cut-off time)

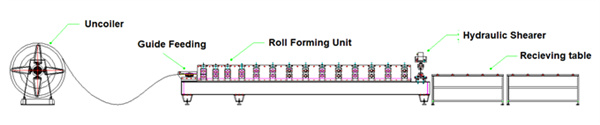

(12) Roller way nos: 15 nos (Double row forming, Figures as follow)

(13) Thickness : (1.5-2) mm

(14) Length Length : ±1.5mm

(15) Roll forming mould : 2 set (different version)

(16) Roll material : Gcr15 quenching treatment (HRC58-62)

(17) Cutting method : Hydraulic cutting after forming

(18 Hydraulic station power : 5.5 KW

3. Unloading Table:

(1) Unloading table size : 2000mm x 2 pcs

(2) Unloading table structure : Roller structure, angle steel welding, no power.

IV. Equipment structure

The main machine is composed of Passive Uncoiler roller forming (Including guide feeding, hydraulic cutting mechanism), loading platform, hydraulic system, electronic control system, etc.

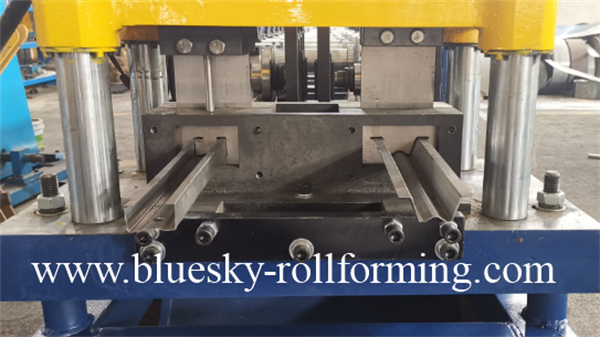

Machine Photo:

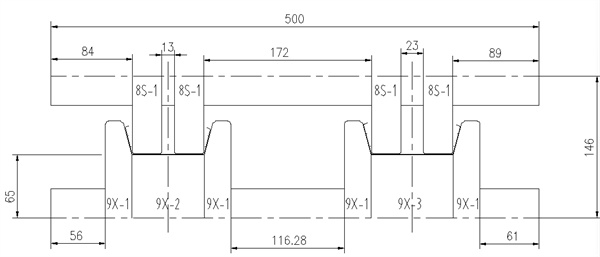

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.5-2mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 4T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |