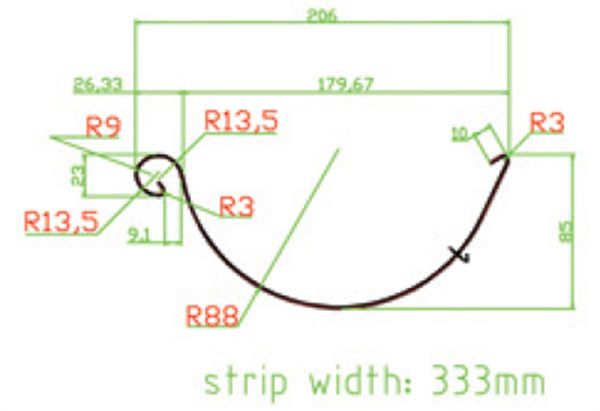

I. Profile Drawing: (according to confirmation by both parties)

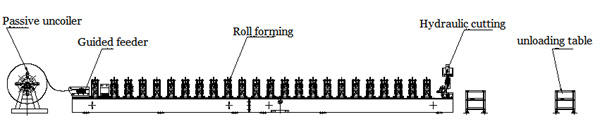

II. Process flow:

Passive unloading -----> Guide Feeding -----> Roll forming -----> Hydraulic Shearing -----> Discharge table.

III. Main Component Data:

1. Uncoiler(2 nos)

(1) Uncoiler : Passive feeding,manual expansion

(2) Loading Weight : 3T

(3) Uncoiler Coil I. D : 508mm

(4) Rolling range : 450-550mm

2. Roll forming machine

(1) Main frame: High quality steel after welding and tempering, Structure.

(2) Forming machine type: Wall plate chain drive.

(3) Shaft material : 45Cr quenching and tempering treatment (HB220-260)

(4) Shaft diameter : Φ70mm (CNC machine processing)

(5) Forming machine motor power : 7.5KW (Hardened surface reducer)

(6) Forming machine line speed : 0-20m\min (excluding cutting time)

(7) Roller way nos :18 nos

(8) Roller hardness : 48-52,surface chrome

(9) Thickness : 0.4-0.8mm (Galvanized steel, Galvanized color steel plate)

(10) Raw material width: width of the actual test plate shall prevail

(11) Length accuracy : ±1.5mm

(12) Transmission way : 1 inch chain drive

3. Cutting mechanism

(1) Cutting type : Hydraulic cutting after forming

(2) Cutting mould material : Alloy tool steel, quenching treatment (HRC58-62)

(3) Cutting blade : 1 pair

(4) Forming cut type material : Alloy tool steel

(5) Length accuracy : ±1.5mm

(6) Heat treatment of cut blade : quenching treatment (HRC58-62)

(5) Hydraulic system power : 5.5kw

(6) Hydraulic station oil pump : vane pump

4. Unloading table

(1) Unloading table size:1500mm x 2 pcs

(2) Unloading table structure:Roller structure, angle steel welding, no power.

Machine picture: (wall panel),

[Machine Size(L*W*H): (7m * 1m * 1.5m).

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.4-0.8mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 18 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |