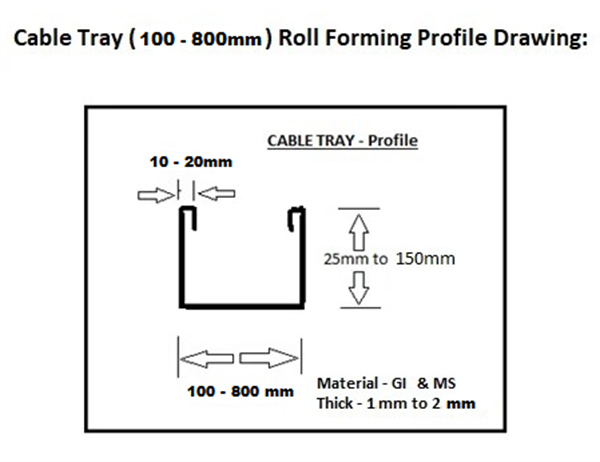

I. Profile Drawing: [Without Punching]

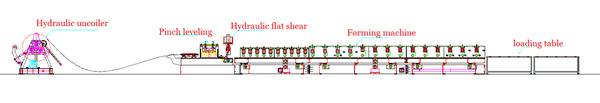

II. Process flow:

10T Hydraulic uncoiling ----> Guide feed ----> Pinch leveling ----> Hydraulic shear (Pre-Cutting System) ----> Roll forming ----> Unloading.

III.Main Component data:

1. Uncoiler:

(1) Uncoiler : Electric feeding, hydraulic expansion (With correction: adjust the steel coil position when producing different size)

(2) Loading Weight : 10T

(3) Uncoiler Coil I. D : 508mm

(4) Rolling range : 450-520mm

(5) Uncoiler power : 5.5KW

(6) Uncoiler hydraulic system power : 3KW

(7) Uncoiler hydraulic system oil pump : Vane pump

(8) Uncoiler main shaft diameter : 190 mm

(9) Uncoiling expansion cylinder diameter : 180 mm

2. Roll Former:

(1) Main frame: Aging treatment of high quality section steel after welding

(2) Leveler structure : 2-roll pinch, 9-roll leveling

(3) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

(4) Shaft diameter : Φ110 mm

(5) Leveling shaft heat treatment mode: surface high-frequency quenching treatment.

(6) Cutting method : Before the hydraulic shear

(7) Shear width : ≤1200mm

(8) Shear thickness : ≤2.0mm

(9) Shear blade material : Cr12mov quenching treatment (HRC58-62)

(10) Hydraulic system power : 7.5KW

(11) Hydraulic system pump : Vane pump

(12) Forming machine structure : Double wall plate type chain drive (automatic horizontal movement)

(13) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

(14) Shaft diameter : Φ80mm (HRB bearing)

(15) Motor power : 11KW+15 KW (Hardened surface reducer)

(16) Forming machine line speed : 0-20 m\min (excluding cut-off time)

(17) Horizontal motor power : total 4.5kw (0.75kw*2 sets for horizontal adjustment of height, 1.5kw * 2 sets for horizontal adjustment of width).

(18) Roller way Nos : 25 Nos. (Production of different specifications

depends on the horizontal shift)

(19) Thickness : 1.0-2.0mm (GI Sheets, MS, Cold Rolled Sheet)

(20) Roll forming mould : 1 set

(21) Expanded width of rolled material : The actual width of the test plate shall prevail

(22) Length : ±1mm (Encoder count, PLC control)

(23) Roll material : Gcr15 quenching treatment (HRC58-62)

(24) Roll hard chromium plating acuity 0.05 m

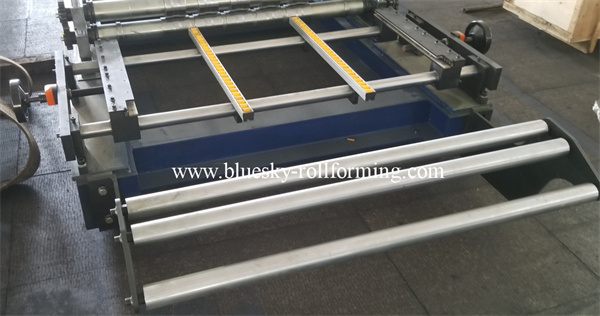

3. Unloading Table:

(1) Receiving table size : 2000mm x 2 pcs

(2) Receiving table structure : Roller structure, angle steel welding, no power.

(3) Voltage :380v, 50Hz, 3ph( as per user)

IV. Equipment Composition:

The main machine is composed of Passive Uncoiler, Roll forming Unit (Including guide feeding, Pre Cutting Hydraulic shear, forming line), unloading platform, hydraulic system, electronic control system, etc.

| Raw Material | Type | Galvanized Sheet, MS, Cold Rolled Sheet |

| Thickness | 1-2 mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 10 T | |

| Main Machine | Main Roller Station | 9 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |