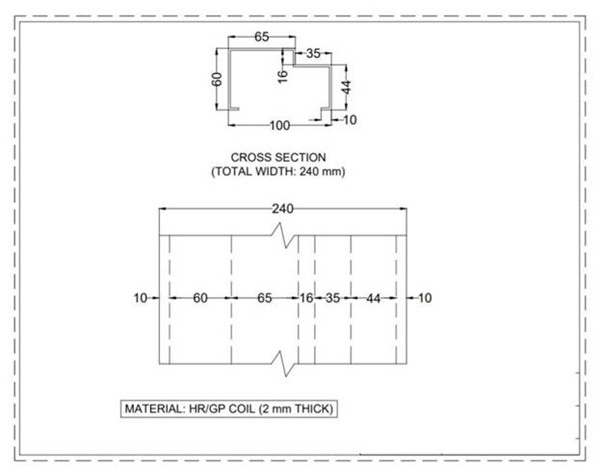

I. Profile drawing: (according to confirmation by both parties)

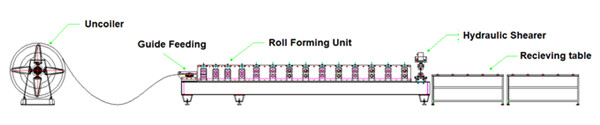

II. Process flow:

Passive uncoiling → Guide Feeding → Forming machine → Hydraulic cutting → Unloading.

III. Components of the Machine Line:

1. Uncoiler:

(1) Uncoiler : Passive feeding, Manual expansion

(2) Loading Weight : 4 T

(3) Uncoiler Coil I. D : 508mm

(4) Rolling range : 450-540mm

2. Roll Former:

(1) main frame: High quality steel after welding and tempering

(2) Pinch Feeding frame type: Side roller type

(3) 2 roller pinch, 7 roller leveling

(4) Leveling roller diameter : about 70mm

(5) Leveling roller material: high quality 40Cr

(6) Leveling shaft heat treatment type: surface high frequency quenching treatment

(7) Forming machine type : wall plate chain drive

(8) Shaft material: 40Cr quenching and tempering treatment (HB220-260)

(9) Shaft diameter : Φ70 (Harbin Bearing)

(10) Forming machine motor power : 11 KW (Hardened surface reducer)

(11) Forming machine line speed : 0-15 m\min (excluding cut-off time)

(12) Roller (Stations) : 15 nos

(13) Thickness : (1.5-2) mm

(15) Length limit: ±1.5mm

(16) Roll forming mould : 1 set

(17) Roll material : Gcr15 quenching treatment (HRC58-62)

(18) Cutting method: hydraulic cutting after forming

(19) Hydraulic station power : 5.5 KW

3. Unloading table:

(1) Unloading table size : 2000mm x 2 pcs

(2) Unloading table structure: Roller structure, angle steel welding, no power.

IV. Machine Photo: (just for your reference)

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.5-2mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Manual expansion |

| Capacity | 4T | |

| Main Machine | Main Roller Station | 15 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |