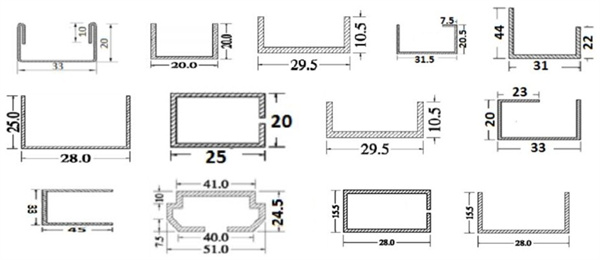

I. Profile drawing: (according to confirmation by both parties)

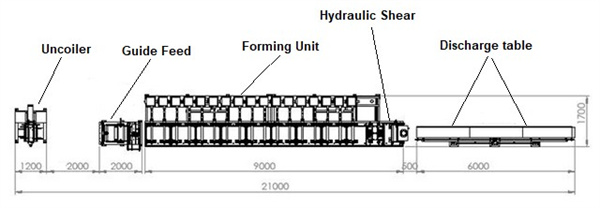

II. Process flow:

Passive Uncoiler -----> Guide feed ------> Roll forming ------> Hydraulic Shearer-----> Discharge table.

III. Components of the Machine Line:

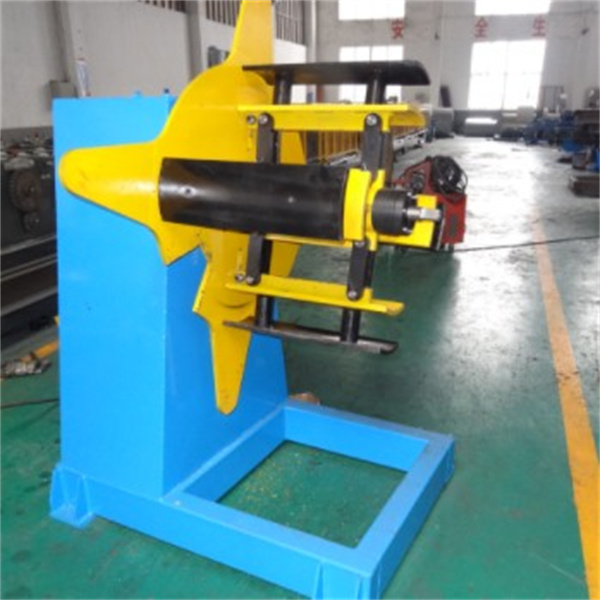

1. Uncoiler

1) Passive feeding, manual tightening

2) Bearing capacity of uncoiler : 5 T

3) Inner diameter of support roll : Φ508

4) Applicable roll width: 0-500mm

2. Roll Former:

1) Forming machine guide feeding frame: side hand wheel

2) Forming machine form: Torii gearbox transmission

3) Number of forming stations: 16 Stations

4) Shaft diameter : 80mm

5) Motor power of forming machine: 15 KW

6) Linear speed of forming machine: 0-15m\min

7) The frame adopts : I-beam welding

8) Rolling thickness : 0.8-3mm

9) Length sizing: 10m ± 1.5mm

10) Roll material: Gcr15 (quenched) hardness 58-60° (6 sets of wheels)

11) Blade material: Gcr12mov

12) Turkish correction head : effectively guarantee product straightness

3.Hydraulic shearer:

4.Unloading Table:

1) Welding of square tube and stripping

| S No | Name of equipment | Quantity |

| 1 | (5 T) passive Decoiler | 1 set |

| 2 | Forming Unit | 1 set |

| 3 | Roll | 6 sets |

| 4 | Discharge table | One piece |

| 5 | Hydraulic station | 1 set |

| 6 | Computer control system | 1 set |

IV.Machine Photo

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.8-3 mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Gearbox | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Gcr12mov |