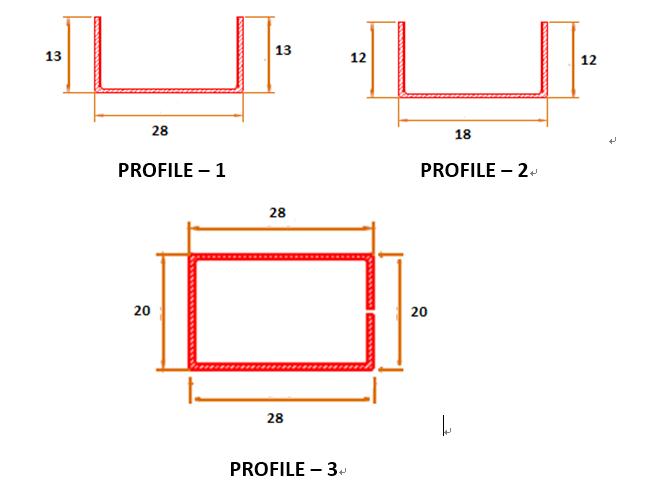

I. Profile: (according to confirmation by both parties)

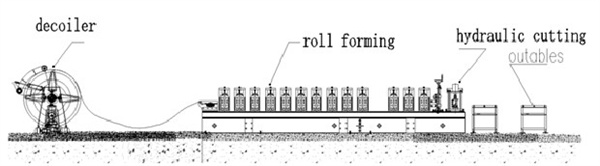

II. Process flow:

Uncoiling (Passive) -----> Guide Feeding -----> Roll Forming -----> Hydraulic cutting -----> Unloading (Discharge table / Outables).

III. Main Component Data:

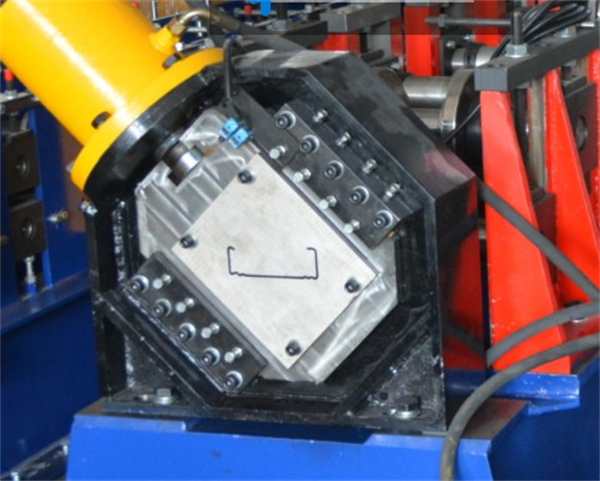

The forming machine design sequence deformation structure is composed of three-phase AC motor, frame, wire cutting wallboard, forming shaft roller, synchronous gear and so on.

1) Main motor power: 5.5KW-4P.

2) Number of forming rollers: 14 forming rollers (dual-row roller molding, shown below)

3) Forming line speed: 0-20 m / min.

4) Thickness of forming plate: 0.8-1.2 mm.

5) Roll material: (two sets) GCR15 hard chrome plated after quenching.

6) Bearing: Harbin bearing

7) Main shaft diameter: Φ70mm. Material: 40cr

8) Wallboard material: A3, CNC finishing.

9) Bearing seat: cast iron material, precision machining, high stability, long service life.

Hydraulic punching and shearing at mechanical shutdown.

1) Cutting method: hydraulic.

2) Blade Material: Cr12

3) Motor power: 5.5 KW;

IV. Machine Photo

IV. Machine Photo

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.3-0.8mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |